-

Menu -

Locations -

Search

John Deere Z530M ZTrak™ Mower with 48-in. Deck

Z530M ZTrak™ Mower with 48-in. Deck

Z500 Series Zero-Turn Mowers

Overview:

- 24 hp* (17.9 kW) V-Twin engine

- 20-in. cut and sewn seat with ComfortGlide™ suspension

- 4-year/300-hour bumper-to-bumper warranty**

Get A Quote

Fields with asterisks* are required. Please email our helpful staff with any questions or comments using the contact form.

Loan Calculator

Use the Loan Calculator to help you determine the financing and payment options that are best for you.

**The accuracy of this calculator and its applicability to your circumstances is not guaranteed. You should obtain personal advice from qualified professionals. This information is provided for illustrative purposes only and does not constitute an application. This notice does not guarantee loan approval, nor is it an offer or commitment to make a loan to you on the above terms.

Send To A Friend

Fields with asterisks* are required. Your friend will receive an email that contains a reference to this page. Please send this email only to people you know who would be interested in this information.

Share This Product:

Features

Comfortable ride delivered by an operator station with adjustable controls and ComfortGlide™ suspension

Operator station

Operator station

Color-coded controls are easy to identify

Color-coded controls are easy to identify

The operator station is designed to provide superior operator comfort for many different operators:

- Large foot platform

- Ample legroom for comfortable operation

- Rubber floor mat for extra foot comfort

- Optional foot pegs (not shown) allow various comfortable positions for operator’s feet

- Adjustable seat position, armrests, and spring suspension to suit each operator

- Control panel conveniently located to the right of the seat

- Adjustable motion-control levers

- Upper and lower positioning combined with forward and rearward tilt offers more legroom and hand positions

Comfortable seat

Comfortable seat with adjustable armrests

Comfortable seat with adjustable armrests

ComfortGlide™ suspension seat adjustment lever

ComfortGlide™ suspension seat adjustment lever

The comfortable seat has two suspension springs, fore-aft seat adjustment, and ComfortGlide suspension:

- A 20-in. (50.8-cm) high-back seat has thick foam padding for good support and comfort.

- Armrests give you extra support.

- 3-in. (7.6-cm) no-tools, fore-aft adjustment makes almost any operator comfortable.

Seat suspension

Long steel seat springs (left)

Long steel seat springs (left)

Long steel seat springs (right)

Long steel seat springs (right)

- Two long steel springs absorb shocks when traveling over rougher areas.

- ComfortGlide is an additional system that allows controlled fore and aft movement of the seat when experiencing undulations in uneven terrain. (M and R Series only).

- Dramatically reduces horizontal vibrations and reduces jarring

- Feel of ride is as if the operator is floating over the ground

- Makes a big improvement to operator ride comfort

- Allows front-to-rear movement, 1-in. (2.5-cm) forward and 1-in. (2.5-cm) rearward, to be absorbed

- One lever with three positions

- Slide seat fore/aft up to 3 in. (7.6 cm)

- Engage isolator function to allow movement up to 1 in. (2.5 cm) fore and aft

- Disengage isolator function to lock seat in position

Foot pegs (standard on R Series, optional on E and M Series)

Foot platform with optional foot pegs installed on Z515E

Foot platform with optional foot pegs installed on Z515E

Foot pegs provide you with more foot placement options and act as convenient handles to remove and replace the foot platform.

NOTE: Foot pegs are standard on the Z530R and Z545R and an optional extra-cost kit on the Z515E and Z530M.

Cup holder and storage compartment

Dual beverage holder

Dual beverage holder

Storage compartment

Storage compartment

The dual beverage holder on the left fender and storage compartment on the right fender add convenience for the operator:

- Room for two drink containers of various sizes for longer mowing jobs

- Storage compartment provides a safe and convenient location to store tools and supplies

NOTE: A storage compartment cover is standard on the Z530R and Z545R.

12-V charge port

12-V charge port

12-V charge port

12-V outlet is located within the storage compartment for the convenience of connecting a variety of electrical and electronic equipment.

Easy-to-see-and-use electric fuel gauge, instruments, and controls

Control console includes an easy-to-read fuel gauge

Control console

Control console

Electric fuel gauge

Electric fuel gauge

The control console is located to the right of the operator station and includes the following:

- Digital display

- Easy-to-read fuel gauge keeps track of the amount of fuel remaining to minimize time spent stopping to refuel.

- Hour meter shows operating hours to keep maintenance on schedule.

- Ignition switch

- Power take-off (PTO) control (yellow)

- Engine speed control (orange)

- Spring-loaded engine choke control so it is not inadvertently left on

- Space for an optional light kit switch

- Space for an additional electric control switch

Fuel sight widow and fill cap

Fuel sight window

Fuel sight window

Fuel sight window and fuel fill cap

Fuel sight window and fuel fill cap

A conveniently located fuel-sight window allows the operator to view the fuel level when approaching the vehicle from the front:

- Semi-clear material makes seeing how much fuel is in the tank quick and easy.

- Large, 3-in. (7.6-cm) diameter fuel-fill opening reduces the chance of spilling when adding fuel.

- Fuel-fill opening is low and angled to make adding fuel easy.

- Cap is tethered to the fuel tank.

- Less chance of fuel cap getting lost

Mower deck lift and cut height

Mower lift pedal and cut-height adjustment

Mower lift pedal and cut-height adjustment

Mower deck cut-height adjustment and transport lock

Mower deck cut-height adjustment and transport lock

Mower deck cutting height can be adjusted from 1 in. (2.5 cm) to 4 in. (10.2 cm) in 0.25-in. (0.64-cm) increments for excellent cut quality and performance:

- A convenient foot-lift pedal is used to raise the mower deck for setting cut height or locking mower in the raised or transport position.

- A lift-assist spring is provided to optimize the effort it takes to raise the mower deck.

Cut-height adjustment and transport lock

- To adjust cut height, simply push down on the foot-lift pedal, place the cut-height pin in the desired location, and release the foot-lift pedal to lower the deck to the chosen height.

- Use the foot-lift pedal to lock the deck in transport mode. Simply depress the pedal all the way and the deck will lock into transport mode.

- To unlock and lower the deck, push down on the foot-lift pedal, pull up on the transport unlock lever, and release the foot-lift pedal to lower the deck to the chosen height.

Adjustable steering levers

Motion-control levers in operating position

Motion-control levers in operating position

Motion-control levers in park position

Motion-control levers in park position

Motion control levers are shaped and located for operator comfort and ease of control.

18-position control lever adjustment, low

18-position control lever adjustment, low

18-position control lever adjustment, high

18-position control lever adjustment, high

The motion-control levers can be adjusted to two different height settings and nine different fore-aft settings:

- Combined height and fore/aft adjustments provide 18 positions

- Increased operator comfort with more leg room and more hand positions

- Adjustable for most precise control of the machine

Tracking adjustment

Tracking adjustment bolts

Tracking adjustment bolts

Tracking adjustment tool

Tracking adjustment tool

Tracking adjustment can be made from the operator seat with the provided tool.

Park brake

Park brake lever

Park brake lever

Motion-control levers in park position

Motion-control levers in park position

The park brake is conveniently located:

- Large lever is easy to use.

- Park brake effectively holds the machine in the parked position.

- Park brake must be engaged (in the upper position) to start the engine.

- Motion-control levers must be in the outward position for the engine to crank.

Brake-and-go logic:

- Park brake must be engaged for the engine to crank.

- Once the engine is started, the park brake must be disengaged before operating the motion-control levers.

- Park brake must be disengaged before operating the motion-control levers or the engine will stall.

Safety interlock system

Interlock switch is located under the seat

Interlock switch is located under the seat

Safety interlocks help prevent operating in an unsafe way:

- The parking brake must be engaged for the engine to crank.

- Parking brake is set when motion-control levers are in the outward position.

- The operator presence system requires the operator to be in the seat to operate the PTO.

- The key switch interlock prevents bypass starting.

- If the operator leaves the seat when the PTO is engaged, the controls are in the operating position, or the parking brake is not set, the engine will shut down.

- The seat interlock switch disengages the mower when the operator leaves the seat.

- The engine will stall if the operator leaves the seat without the motion-control levers in the outward position and the parking brake set.

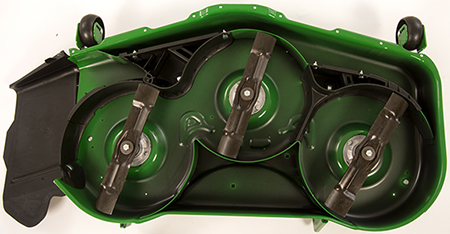

Superior cut quality and productivity from the flat-top design of Accel Deep™ Mower Decks

ZTrak™ Z515E with 48A Mower Deck

ZTrak™ Z515E with 48A Mower Deck

ZTrak Z515E with 48A Mower Deck

ZTrak Z515E with 48A Mower Deck

The 48-in. (122-cm), 54-in. (137-cm), and 60-in. (152-cm) Accel Deep Mower Decks are a forged-steel, deep, flat-top design that delivers excellent cut quality, productivity, cleanliness, durability, and versatility. Optimal performance and dispersion of clippings is provided, even at faster mowing speeds or in tall grass:

- 4.83-in. (12.3-cm) (48A/54A) or 4.91-in. (12.5-cm) (60A) depth throughout the entire deck shell for optimum mowing, mulching, and bagging performance.

- Optional MulchControl™ system provides superior mulching performance and versatility.

- Forged-steel design eliminates sharp edges and corners where material can build up and diminish mowing performance.

- Mower deck is suspended from the vehicle for a smooth and level cut.

- Adjustable mower wheels, positioned just above ground level, help reduce scalping.

- 0.25-in. (6.4-mm) cut-height increments allow the mower to be set at the desired cut height

Compatibility

| Mower Deck | Models | Mulching (optional) | Material collection (optional) |

| 48-in. (122-cm) Accel Deep (48A) | Z530M | MulchControl system | 6.5-bu (230-L) two-bag Power Flow™ system |

| 54-in. (137-cm) Accel Deep (54A) | Z515E, Z530M | MulchControl system | 6.5-bu (230-L) two-bag Power Flow system |

| 60-in. (152-cm) Accel Deep (60A) | Z515E, Z530M | MulchControl system | Not available |

Productivity - getting the job done fast

Trim side of Accel Deep Mower Deck

Trim side of Accel Deep Mower Deck

Deep mower-deck forging delivers high productivity, which gets the job done fast. It allows room for the cut and suspended material to exit the deck quickly, reducing the amount of recutting so more power is available to process incoming grass:

- Greatly improves the mower’s capacity to maintain excellent mowing performance and cut quality in difficult mowing conditions and at higher speeds

- Even in mulching mode, cut evenness is improved compared to other designs because the additional depth allows for continuous circulation, optimal recutting, and an even distribution of clippings.

Large discharge opening is both high and wide to handle more material:

- Gives a smooth, even discharge of clippings at all mowing speeds

- Reduces the chance of plugging, especially important when operating in wet, thick, or dense grass and when bagging

Cleanliness - for the mower and the operator

Accel Deep Mower Deck, trim side

Accel Deep Mower Deck, trim side

Cleaning a mower deck is one of the most frequent maintenance activities. The flat-top shape of the deck forging is optimal for keeping itself and the operator clean:

- There are few places to catch and hold material on top and underneath the deck.

- Top of deck stays cleaner, reducing time and effort needed for cleaning and service

- Underside of deck is self-cleaning to maintain optimum performance without buildup of material to interfere with the flow of air and clippings

- Less need to clean and remove buildup of material from underside of deck

- The depth of the Accel Deep Mower Deck minimizes the amount of material that escapes from the front of the deck.

- Limited amount of material drifts onto the operator and mower deck

- Even for material discharged out the chute, less recutting results in larger pieces that are less likely to end up on the operator

- Mulching prevents the discharge of material completely and MulchControl makes mulching a practical solution for most mowing situations.

Mower wash port

Mower wash port

Mower wash port with hose connector

Mower wash port with hose connector

A wash port and hose connector are provided to make cleaning the underside of the mower deck easy.

How MulchControl works

MulchControl baffle in open position

MulchControl baffle in open position

MulchControl baffle in closed position

MulchControl baffle in closed position

MulchControl is an innovative, simple design that is easy to use and maintain:

- The MulchControl attachment includes baffles to control the flow of material under the deck.

- The MulchControl baffle, or divider, between the left and middle spindles is about halfway down. The height is designed to balance the mulching and side-discharge modes.

- When the MulchControl baffle is open, the divider between the left and middle spindles passes a portion of the material to the discharge opening, along with the material from the middle and right spindle areas.

- When the MulchControl baffle is closed, the material stays within the deck and gets chopped into mulch and deposited in the turf.

Superior durability is designed in

Hinged spindle pocket cover

Hinged spindle pocket cover

Double-captured mower wheel

Double-captured mower wheel

Accel Deep Mower Decks have strong spindle pockets to keep the blades aligned, even after years of tough service:

- Forged from strong 10-gauge, 0.135-in. (3.4-mm) steel

- Ribs in the deck shell add strength where it is needed.

- Mower wheels are double captured:

- Provides greater strength and durability for longer, trouble-free life

- Single-bolt adjustment makes setting wheels to the correct cutting height quick and easy

- Low-tension belt-drive design reduces the side load on engine lower bearings and mower deck bearings for longer life.

- A 5/8-in. (16-mm) diameter solid-steel rod side guard provides extra strength and protection.

- Dual-stage E-coat and powder-paint coatings provide extra protection from rust.

Versatility - easy to change between side discharge, mulch, and bagging modes

Accel Deep Mower Decks are designed for maximum versatility, providing the greatest ease in changing from one mower discharge mode to another:

- With MulchControl, changing from side discharging to mulching or vice versa is done with the simple flip of a lever.

- On 48A and 54A Mower Decks, the Power Flow rear bagger can be used with MulchControl by simply using the MulchControl lever to move the mulch baffle to the side-discharge position.

MulchControl option

The MulchControl system for Accel Deep Mower Decks is an optional field-installed attachment and makes mulching practical for many mowing situations because it not only does an excellent job of mulching, but it also allows the mower to be easily converted for times when it is more desirable to side discharge or collect lawn material.

Advantages of mulching grass clippings include:

- A beautiful looking lawn

- Grass clippings not blown onto the operator, driveways, or flower beds

- Less fertilizer required

- Elimination of the effort needed to dispose of clippings

MulchControl handle

MulchControl handle

- The MulchControl handle is located on top of the mower deck and used to open and close the discharge baffle.

- The operator is required to get off the machine in order to engage or disengage mulch mode.

- Changing from mulching to side discharge or vice versa takes only a few seconds.

MulchControl is well-suited to the following mowing situations:

- Usually mulch, but side discharge when grass gets too long

- Usually side-discharge, but would like to be able to close the chute to control clippings

- Always mulch a main lawn, but often side discharge secondary lawns

- Bag clippings, but want to go farther before emptying bags

MulchControl puts the operator in control of the clippings. The operator can have all the benefits of mulching with the ability to easily change to side discharge or bagging when needed.

While in the side-discharge mode, MulchControl still mulches about one third of the material. Therefore, the side-discharge mode is essentially a partial mulch mode. This can be an advantage when side discharging or bagging, as it helps reduce the amount of material being discharged. Other times this could work as a disadvantage:

- When cutting strong southern grasses, such as Zoysia and Bermuda

- When cutting in wet, high-growth conditions, such as those found in the Pacific Northwest United States

- When optimum bagging and lawn cleanup is desired

6.5-bu (230-L) Power Flow rear bagger (not available for 60-in. [152-cm] Mower Deck)

Power Flow rear bagger

Power Flow rear bagger

An optional 6.5-bu (230-L) Power Flow rear bagger material collection system (MCS) is available. It provides an efficient means of collecting grass clippings and leaves:

- The Power Flow blower and chute are easy to install.

- The Power Flow blower swings out for easy cleanout and cleanup. The hopper design provides modern styling, great bagging performance, cleaner operation, and easy-to-empty bags:

- Easy-to-attach Power Flow blower (ordered separately)

- Easy-to-attach chute (ordered separately)

- Air exhaust duct

- Convenient spring-latch

- Airflow fill indicator

- Quik-Tatch™ mounting

- Sealed hopper top

- Loose-knit bags available

- Hopper kit comes with ballast bracket

Superior performance and long life with a smooth and powerful 44.3-cu in. (726-cc) V-twin engine

V-twin engine

V-twin engine

Convenient cover for air cleaner and cleanout port service

Convenient cover for air cleaner and cleanout port service

The Z530M and Z530R have a large 44.3-cu in. (726-cc) displacement engine with premium features that provide superior performance and reliability.

- Easy inspection and removal of any debris that may have collected using two large cleanout ports that are integrated into the engine shroud over the cylinder heads.

- Engine service times, reliability, and life are increased with the use of premium engine oil and air filtering systems, as well as the cooling design.

Experience plenty of power and torque to handle tough mulching, mowing, and bagging conditions with the 24-hp (17.9-kW) V-twin engine:

- Greater torque, lower vibration, and improved sound quality from the V-twin cylinder design

- Fast starts with electronic ignition

- Long engine life with cast-iron cylinder liners

- Excellent power and fuel economy with overhead valves

- Reliable operation with in-line fuel filter

Engine easy access

Engine easy access

The engine speed lever and choke control lever are separate controls:

- The engine speed lever is easy to use - there is no need to worry about pushing too far and engaging the choke like on single throttle/choke lever systems.

The engine area is open for visibility to important service points, making it easy to inspect and clean the engine.

4.5-gal. (17-L) fuel capacity for extended mowing times

Fuel tank and fuel sight window

Fuel tank and fuel sight window

Fuel fill cap

Fuel fill cap

The 4.5-gal. (17-L) fuel tank is easy to fill and has a sight-level window and dash-mounted gauge:

- Longer times between refills with the large tank

- Easy to see how much fuel is in the tank by viewing the sight gauge when approaching from the front of the machine

- Easy filling and minimum chance of spills with a large, 3-in. (7.6-cm) diameter fuel opening that is low and angled

John Deere recommends the use of fuel stabilizer in gasoline. See Fuel-Protect for gasoline engines (8 oz [237 mL]) for more information.

Protective zone around the operator is provided by the rollover protective structure (ROPS)

Clean, open operator station

Clean, open operator station

Standard folding ROPS

Standard folding ROPS

The spacious operator station has been designed for comfort, visibility, and ease of use:

- Getting on and off easy with the flat operator platform.

- Convenient-to-use controls are located close to the operator.

- Operator controls are color coded and designed for easy identification and operation.

The ROPS and seat belt work in conjunction to provide a protective zone around the operator:

- It reduces the operator’s risk of being crushed under the vehicle should it overturn.

- In most situations, the ROPS limits the overturn to little more than 90 degrees.

- When used with a seatbelt, the ROPS is very effective in preventing deaths and serious injuries.

- Use of the seat belt is recommended when operating with ROPS in the upright position.

ROPS folded at intermediate position

ROPS folded at intermediate position

ROPS folded down

ROPS folded down

Foldable ROPS and retractable seat belt are standard equipment:

- Handles on the position pins provide a good grip and make changing the angle of the ROPS easier.

- The door height of most garages will accommodate the machine with ROPS in the fully raised position.

- Easy-fold ROPS improves the ability to store the ZTrak™ mower in structures with a lower door opening.

| Model | Height at top of ROPS in fully raised position |

| Z515E, Z530R | 70.1 in. (178 cm) |

| Z530R, Z545R | 70.7 in. (179.6 cm) |

Great appearance, reliability, and performance delivered by a heavy-duty design

Front and side lights (option on Z515E and Z530M)

Front and side lights (Z545R shown)

Front and side lights (Z545R shown)

The attractive design includes a provision for light-emitting diode (LED) lighting:

- Two front lights face forward for front visibility.

- Side lights are positioned to provide excellent visibility of the mower deck.

NOTE: Lights are standard on the Z530R and Z545R and optional on the Z515E and Z530M.

Formed and welded steel frame

Solid steel tube front frame

Solid steel tube front frame

Strong rear frame for support and protection

Strong rear frame for support and protection

A strong, welded steel frame provides solid, reliable support for the machine components and operator:

- Heavy-duty 1.5- x 2-in. (38- x 51-mm) frame tubing for durability

- Rear frame provides solid support and protection for the engine

Rear hitch (option on Z515E and Z530M)

Rear hitch shown with optional rear bumper

Rear hitch shown with optional rear bumper

Strong frame is designed to accommodate a rear hitch that can be used to pull a variety of lawn equipment:

- Can support up to 100 lb (45.4 kg) of tongue weight

- Can pull equipment weighing up to 250 lb (113.4 kg)

NOTE: The rear hitch is standard on the Z530R and Z545R and optional on the Z515E and Z530M.

Large, smooth-riding front caster wheels

Large caster wheel

Large caster wheel

Caster wheel spindle housing

Caster wheel spindle housing

Large front caster wheels provide a smooth ride and level cut:

- Large, 13x5.0-6 tires travel over bumps more smoothly

- Pneumatic tires for the smoothest ride

- Better performance on slopes

Caster wheels turn easily on two maintenance-free sealed ball bearings for both the spindles and the wheel axles:

- Long, trouble-free life

- Designed to give smooth turns without damage to the turf

- Large rear drive wheels for a smooth ride and level cut

Large rear tires

Large diameter rear tire

Large diameter rear tire

Rear tires have high-quality tread and optimum size for superior traction and smooth ride:

- Tire size is 22x9.5-10.

- Tread pattern is optimized for excellent traction and minimum turf damage.

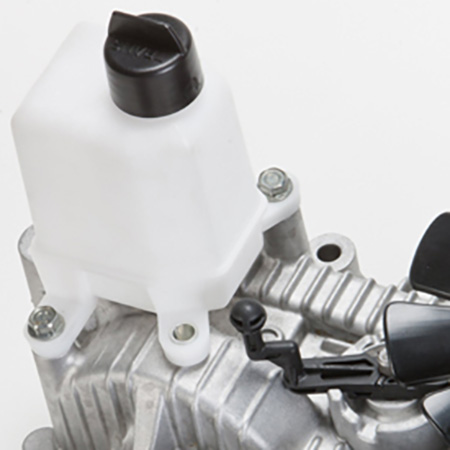

Maximize mowing efficiency with dual transmissions that offer mowing speeds up to 8 mph (12.9 km/h)

Unitized hydrostatic transmission

Unitized hydrostatic transmission

Dual unitized transmissions efficiently power the ZTrak™ mower forward and reverse and provide steering capability:

- Experience excellent hillside stability with transmissions that are set low in the vehicle.

- Tuff Torq® TZT7-D transmissions are reliable and durable.

- Beefed-up 1-in. (2.5-cm) axles for greater strength

- Maintenance-free, unitized transmissions are sealed and have no hose connections to leak hydraulic fluid.

- Four-bolt hubs provide a reliable and convenient wheel-mounting system.

Transmission expansion tank and tow-valve lever

Transmission expansion tank and tow-valve lever

Tow valve control lever

Tow valve control lever

Tow-valve controls are provided for each transmission and are located on the transmission near the expansion tanks:

- Easy to reach and use

- Allow the vehicle to be moved without the engine running

Adjustable steering levers

Motion-control levers in operating position

Motion-control levers in operating position

Motion-control levers in park position

Motion-control levers in park position

Motion control levers are shaped and located for operator comfort and ease of control.

18-position control lever adjustment, low

18-position control lever adjustment, low

18-position control lever adjustment, high

18-position control lever adjustment, high

The motion-control levers can be adjusted to two different height settings and nine different fore-aft settings:

- Combined height and fore/aft adjustments provide 18 positions

- Increased operator comfort with more leg room and more hand positions

- Adjustable for most precise control of the machine

Tuff Torq is a trademark of Kanzaki Kokyukoki Mfg. Co., Ltd.

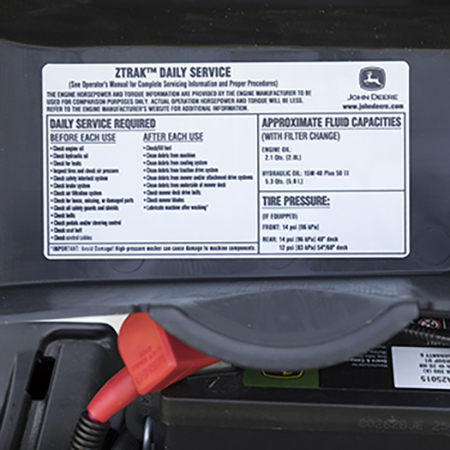

Convenient machine service includes 4-year bumper-to-bumper warranty

Service interval decal

Service interval decal

A convenient service interval decal provides basic maintenance information:

- Provides a quick reference for keeping recommended service up to date

- Located under the seat for easy viewing

Quick response (QR) codes link to owner information web pages

Example product identification number (PIN) label with QR code

Example product identification number (PIN) label with QR code

John Deere riding lawn mowers are supported by owner information web pages that include links to:

- Safety and how-to videos

- Operator’s manuals

- Parts catalog

- Maintenance reminder sheets

- Attachments

- Warranty statements

To speed access to owner information web pages, a QR code is printed onto a PIN label located under the seat on the battery cover. Since each vehicle model has its own web page, the links are specific to the owner’s model. The QR code also includes the vehicle’s unique PIN which allows for additional customization of the owner information web page in the future.

Engine service

Z530M engine

Z530M engine

Cleanout port and air filter access

Cleanout port and air filter access

The engine is easy to service and takes a minimal amount of time:

- Air filter is on top of the engine and the cover flips up for easy access.

- Cooling fin cleanout ports are located under the air cleaner cover.

Engine oil fill/check and oil drain tube

Engine oil fill/check and oil drain tube

- Engine oil fill/check tube is easy to see and reach.

- Oil drain tube is provided for easier, cleaner oil changes.

Mower service

Foot platform easily removed for access to mower

Foot platform easily removed for access to mower

The footrest area is removable without tools to easily access the mower deck for service:

- Easy to clean grass off the top of the mower

- Provides convenient access to the mower drive

Flat-top deck and flip-up spindle cover

Flat-top deck and flip-up spindle cover

Mower deck leveling gauge and tracking wrench

Mower deck leveling gauge and tracking wrench

Accel Deep™ Mower Decks have features that make them easy to service:

- Flat-top design minimizes places for debris to collect.

- Spring-loaded, flip-up belt guards make removing debris easy.

- Deck-leveling gauge and wrench are conveniently stored on the machine

Tracking adjustment

Tracking adjustment tool

Tracking adjustment tool

Tracking adjustment can be made from the operator seat with the provided tool.

Warranty

Limited bumper-to-bumper warranty for new turf and utility equipment (U.S. and Canada only):

- Z530M - 48 months or 300 hours, whichever comes first

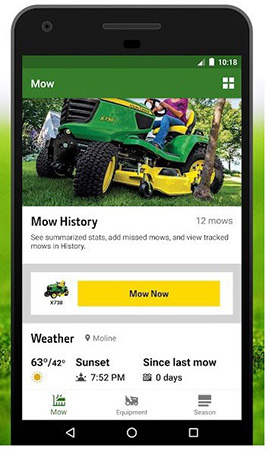

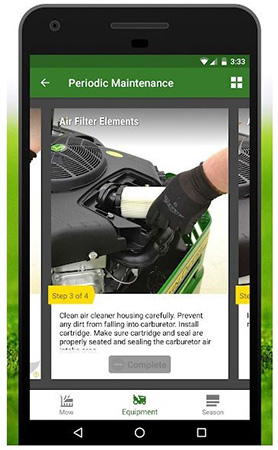

Help maintain your mower and lawn with the MowerPlus™ app and connector

MowerPlus home screen

MowerPlus home screen

MowerPlus maintenance screen

MowerPlus maintenance screen

Overview

Keep a mower running its best and know how it mows with the John Deere MowerPlus app. Simply scan the mower’s barcode to get custom information about the mower.

Benefits

- Engine hours, fuel level, and battery health (as compatible)

- Mowing history with time, distance, area, and speed

- Current day and five-day weather forecast based on location

- Walk-through setup guides

- Expert mowing tips

- Useful attachments for future purchase

- Periodic maintenance reminders

- Safety instructions

To download the free MowerPlus app, visit the Apple® App Store® or Google Play™ store.

Additional details

MowerPlus connectors (sold separately)

MowerPlus Hour Meter Connector

MowerPlus Hour Meter Connector

MowerPlus Deluxe Smart Connector, with a phone

MowerPlus Deluxe Smart Connector, with a phone

Three MowerPlus connectors are available to transmit vehicle information to the MowerPlus app.

BUC10510 MowerPlus Hour Meter Connector is for use with:

- Model year 2003 to 2020 100 Series Tractors, including all models with an E, D, LA, or L prefix

- Model year 2015 to 2020 S240 Tractors (serial number -880,000)

- S100, S110, S140, and S220 Tractors

BUC10929 MowerPlus Deluxe Smart Connector is for use with:

- All S120, S130, S160, S170, and S180 Tractors

- Model year 2021 and newer S240 Tractors (serial number 880,001-)

- Model year 2021 and newer Z515E, Z530M, Z530R, and Z545R (serial number 010,001-)

BUC10537 MowerPlus Smart Connector is for use with:

- Model year 2016 and newer Select Series X300 and X500 Tractors

All the MowerPlus connectors transmit engine hour information to the app, making it easy to track maintenance intervals. The MowerPlus Smart Connector and MowerPlus Deluxe Smart Connector also transmit the fuel level.

MowerPlus connectors require the MowerPlus app on a mobile device to use. The John Deere MowerPlus app and operating system requirements can be found in the mobile device’s app store. The MowerPlus app is only available in the English language, and it is not available in all countries. BUC10510 MowerPlus Hour Meter Connector requires iOS® version 10 or higher and is not compatible with Android™ operating systems.

Apple and App Store are trademarks of Apple, Inc. Google Play and Android are trademarks of Google LLC. iOS is a trademark of Cisco Technology, Inc. used under license by Apple Inc.

Specifications

Key Specs

| Engine power | 24 hp 17.9 kW |

|---|---|

| Engine model number | FR730V |

| Forward speed | 0-8 mph 0-12.9 km/h |

| Front caster tires | 13x6.5-6 |

| Drive tires | 22x9.5-10 |

| Seat back height | High back with armrests and ComfortGlide™, 20 in. 50.8 cm |

| Width of cut | Accel Deep™ mower deck, 48 in. 122 cm Accel Deep mower deck, 54 in. 137 cm Accel Deep mower deck, 60 in. 152 cm |

| Mulching system | Optional MulchControl™ attachment, 48 in. 122 cm Optional MulchControl attachment, 54 in. 137 cm Optional MulchControl attachment, 60 in. 152 cm |

| Warranty | 4 year or 300 hour bumper-to-bumper* (*Term limited to years or hours used, whichever comes first, and varies by model. See the LIMITED WARRANTY FOR NEW JOHN DEERE TURF AND UTILITY EQUIPMENT at JohnDeere.com or JohnDeere.ca/TUWarranty for details.) |

| Battery | |

| Charger |

Engine

| Power | 24 hp 17.9 kW |

|---|---|

| Model number | FR730V |

| Displacement | 44.3 cu in. 726 cc |

| Cylinders | V-twin |

| Lubrication | Full pressure with replaceable filter, capacity, 2 U.S. qt 1.9 L |

| Type | Overhead valve |

| Battery | 12 V 300 CCA |

| Choke/speed control | Separate control levers |

| Cooling method | Air |

| Fuel tank capacity | 4.5 U.S. gal. 17 L |

| Fuel gauge | Electric gauge and fuel level sight line |

Drive train

| Dual hydros | Tuff Torq® TZT7-U with 1-in. (2.5-cm) axles |

|---|---|

| Hydraulic pumps | |

| Wheel motors | |

| Battery | |

| Charger | |

| Transmission |

Travel speed

| Forward speed | 0-8 mph 0-12.9 km/h |

|---|---|

| Reverse speed | 0-4 mph 0-6.4 km/h |

| Speed and direction control | Twin premium levers |

| Control adjustment | 2-height/9-fore-aft, 18 positions |

Chassis

| Frame | Heavy-duty frame tubing |

|---|---|

| Primer/paint | E-coat/powder |

| Front caster tires | 13x6.5-6 |

| Front caster bearings | Sealed ball bearings |

| Drive tires | 22x9.5-10 |

| Hour meter | Yes |

| Service interval decal | Yes |

| Storage compartment | Yes |

| Cup holder | Yes |

| Maximum towing capacity | 250 lb 113 kg |

Seat

| Seat back height | High back with armrests and ComfortGlide, 20 in. 50.8 cm |

|---|---|

| Fore-aft adjustment | While seated, 3 in. 7.6 cm |

| Seat suspension | Two springs and ComfortGlide |

Lift system

| Type | Foot lift |

|---|---|

| Mower cut height | 1-4 in. 2.5-10.2 cm |

| Cut height increments | 0.25 in. 0.64 cm |

| Preset cut height | Yes |

Mower deck

| Width of cut | Accel Deep mower deck, 48 in. 122 cm Accel Deep mower deck, 54 in. 137 cm Accel Deep mower deck, 60 in. 152 cm |

|---|---|

| Type | Side discharge |

| Mower deck material | 10 gauge 0.135 in. 3.4 mm |

| Mower drive system | V-belt |

PTO

| Type | Electric, 105 lb-ft 142.4 Nm |

|---|---|

| Drive | V-belt |

Dimensions

| Wheelbase | 49.2 in. 1250 mm |

|---|---|

| Overall length | 76.9 in. 1953 mm |

| Width without mower | 46.6 in. 1184 mm |

| Width with mower | 48A: 62.8 in. 1595 mm 54A: 68.6 in. 1742 mm 60A: 73.4 in. 1864 mm |

| Width with mower (deflector raised for storage) | 48A: 53.9 in. 1370 mm 54A: 59.7 in. 1517 mm 60A: 65.6 in. 1667 mm |

| Height | ROPS in folded position: 48.6 in. 1235 mm ROPS in raised position: 71.1 in. 1806 mm |

| Weight | With mower and fuel, 48A, 772 lb 351 kg With mower and fuel, 54A, 780 lb 355 kg With mower and fuel, 60A, 788 lb 358 kg |

Operation

| Rollover protective structure (ROPS) | Yes |

|---|---|

| Slope operating limit | 15 degrees, 10 degrees with an MCS |

| Operator presence system | Yes |

| Park brake interlock | Yes |

| Operator video | Yes |

Buyer's notes

| Note 1 | Mower wash port makes cleaning the deck easier |

|---|---|

| Note 2 | Flip-up foot platform for easy service access |

| Note 3 | 18-position adjustable motion-control levers |

| Warranty | 4 year or 300 hour bumper-to-bumper* (*Term limited to years or hours used, whichever comes first, and varies by model. See the LIMITED WARRANTY FOR NEW JOHN DEERE TURF AND UTILITY EQUIPMENT at JohnDeere.com or JohnDeere.ca/TUWarranty for details.) |

Optional attachments

| Mulching system | Optional MulchControl attachment, 48 in. 122 cm Optional MulchControl attachment, 54 in. 137 cm Optional MulchControl attachment, 60 in. 152 cm |

|---|---|

| Rubber floor mat | Foot platform only |

| Sun shade | Optional |

| Mounted sprayer | No |

| Protective cover | No |

| Light kit | Optional 4-point LED Light kit |

| Material collection system | Power Flow rear bagger, 6.5 bu 230 L Not available on 60A |

Additional information

| Manufacturing location | Greeneville, Tennessee, USA |

|---|---|

| Date collected | 1-Dec-21 |

Contact Us

-

325 Walt Messick Road

Harrington, Delaware 19952

Phone: (302) 398-3729

Toll Free: (800) 237-1272