-

Menu -

Locations -

Search

John Deere 959MH Tracked Harvester

Double tap to zoom

959MH Tracked Harvester

Tracked Harvesters

Overview:

- Net Power: 246 kW (330 hp) at 1,900 rpm

- Max. Boom Reach: 10.34 m (33 ft. 11 in.)

- Tractive Effort: 373 kN (83,880 lbf)

Get A Quote

Fields with asterisks* are required. Please email our helpful staff with any questions or comments using the contact form.

Loan Calculator

Use the Loan Calculator to help you determine the financing and payment options that are best for you.

**The accuracy of this calculator and its applicability to your circumstances is not guaranteed. You should obtain personal advice from qualified professionals. This information is provided for illustrative purposes only and does not constitute an application. This notice does not guarantee loan approval, nor is it an offer or commitment to make a loan to you on the above terms.

Send To A Friend

Fields with asterisks* are required. Your friend will receive an email that contains a reference to this page. Please send this email only to people you know who would be interested in this information.

Share This Product:

Features

Operate in comfort

Inside the cab of a 953M

Inside the cab of a 953M

Floor-to-ceiling front window

Floor-to-ceiling front window

Operating for long hours is common. As the day goes on, maintaining consistent productivity is important. One factor in keeping high, consistent productivity is a comfortable operating environment. The M-series boasts greatly increased window area for better visibility and more cab space over prior models. Low-effort electrohydraulic (EH) controls allow you to customize the button and lever layout to your preference and save your settings when switching between operators.

- Large and spacious operator station designed with operator input

- Ergonomic controls and increased cab volume over prior models

- Floor-to-ceiling front window, large side windows, skylight, and optional floor window (standard on leveling machines) significantly expands operator visibility

- Optional heated and ventilated seat

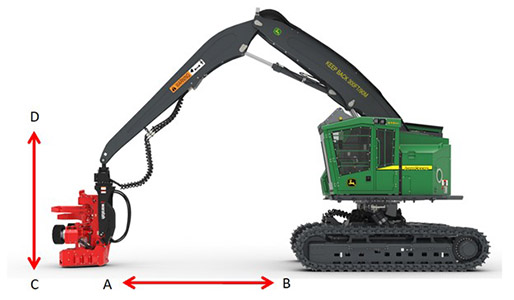

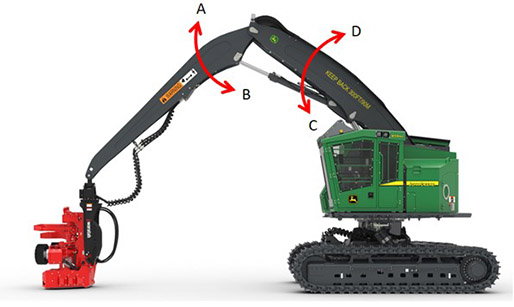

Intelligent Boom Control (IBC) enables precise boom movements

Boom control pattern with IBC

Boom control pattern with IBC

Boom control pattern without IBC

Boom control pattern without IBC

Boom joystick pattern

Boom joystick pattern

With IBC |

Without IBC |

|

A |

Extend |

Stick out |

B |

Retract |

Stick in |

C |

Lower |

Hoist down |

D |

Raise |

Hoist up |

Intelligent Boom Control (IBC) smooths boom operations, making them more precise and efficient, to increase operator productivity compared to a Deere tracked harvester without IBC. With IBC, you no longer need to control each boom function independently. Just control the direction of the head with a single lever command, and IBC will automatically guide the boom and cylinders accordingly. IBC also utilizes adaptive swing control to adjust the swing speed based on the overall position of the head. This makes controlling the head more precise and intuitive, especially for new operators, compared to machines without IBC.

- Customizable control pattern and boom motions

- More efficient and consistent boom movements

- Enhanced cylinder cushioning reduces shock loading at end-of-stroke

- Overall improved operator experience

- Simple and intuitive to operate

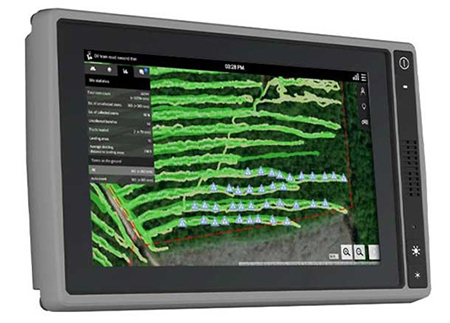

Gain valuable insights with Precision Forestry solutions

Mobile device using JDLink™

Mobile device using JDLink™

TimberMatic™ Maps monitor displaying live production data

TimberMatic™ Maps monitor displaying live production data

Machine Health Monitoring Center

Machine Health Monitoring Center

Now included in base machine, the JDLink telematic system provides the foundation for John Deere’s Precision Forestry solutions. These systems help optimize your machine, your uptime, and your jobsites, which ultimately lead to improved production efficiency.

- JDLink connectivity enables you to view several parameters of your machine, including its location, fuel level, average fuel burn rate, idle time, machine utilization, and much more

- When enabled, John Deere Connected Support™ allows the dealer to provide remote diagnostics, rapid service response with the right part in hand, and parts availability; all to maximize machine uptime

- John Deere’s centralized Machine Health Monitoring Center analyzes data from thousands of connected machines, identifies trends, and develops recommended actions to help prevent downtime

- TimberMatic Maps gives enhanced visibility to the jobsite, which streamlines communication and increases efficiency

- TimberManager™ provides remote visibility to your operation from any device, allowing you to make smart business decisions based on real-time production data

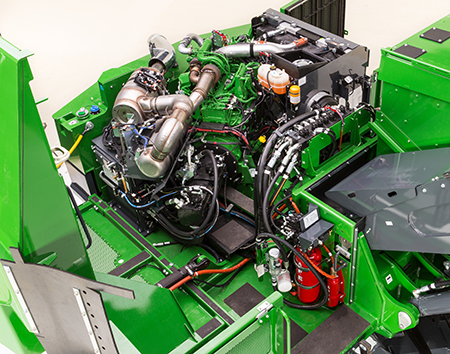

Serviceability within easy reach

An operator servicing a 959M

An operator servicing a 959M

959M with the cooler door open

959M with the cooler door open

959M with the enclosure opened

959M with the enclosure opened

Easy access to service components helps operators perform daily checks and any scheduled maintenance, which helps minimize unplanned downtime and costly repairs down the road. The 900M-series tracked machines feature a fully opened enclosure and service doors for excellent access to all scheduled maintenance areas.

- Smart debris management designed to keep your workspace free and clear

- Variable-speed reversing fan helps minimize debris build-up in the cooling package

- Swing-out doors provide wide-open access to the cooling package

- Optional vacuum pump for convenient servicing of hydraulic components

- Grease banks for servicing hard-to-reach joints

- Large fuel tank extends intervals between fill-ups

- Remote diagnostics and machine monitoring with JDLink™

- Available side walkways provide direct access to the enclosure from the operator station*

*Side walkways are optional features on 903M, 953M, and 953MH models

Sure-footed stability

U7 undercarriage

U7 undercarriage

The M-series undercarriage is purpose built to handle severe forestry applications while maintaining maneuverability, especially in thinning operations. The track frames are shaped to deflect debris while also providing strength and stability.

- Long, wide undercarriage provides solid balance to maximize stability

- Exceptional tractive effort for negotiating difficult or steep terrain, deep snow, and swamps

- Optional closed-loop hydrostatic drive on 800M/MH models for increased multifunctioning performance

- Various track pad widths and grouser types are offered to best suit the machine to its application

- Optional tri-track helps prevent premature wear due to track twisting

Maximize stability on steep slopes

959ML working on a hillside

959ML working on a hillside

The expansive leveling envelope tilts up to 26-degrees forward for excellent steep-slope operation. Combined with a long and wide undercarriage, the leveling system maximizes performance in challenging terrain.

- Additional operator comfort when maneuvering on slopes

- Common undercarriage between the 859M and 959M leveling machines

- Maximizes boom and swing performance when working on slopes

- Provides exceptional stability and continuous machine operation on extreme slopes

Slope indicator

Slope indicator on the primary display unit (PDU)

Slope indicator on the primary display unit (PDU)

An available option on all leveling M-series machines, the slope-monitoring system measures the actual ground-slope angle the machine is working on and displays it on the in-cab monitor, for more confident operation in tough steep-slope conditions and potentially greater overall efficiency.

Specifications

DRIVELINE

| Engine Manufacturer | John Deere |

|---|---|

| Engine Model | PowerTech Plus 6090 PSS |

| Displacement, ltr (Inches³) | 9 (549) |

| Rated Speed, rpm | 1900 |

| Engine Output, kW (hp) | 246 (330) |

| Engine Torque, Nm (lbf / ft) | 1392 (1027) |

| Carrier Rollers - Each Side | 2 |

| Track Rollers - Each Side | 9 |

| Track Shoe Width, mm (inches) | 610 (24) |

DIMENSIONS

| Height Over Cab, mm (ft/in) | 4030 (13 ft 3 in) |

|---|---|

| Width, mm (ft/in) | 3200 (10 ft 6 in) |

| Overall Track Length, mm (ft/in) | 4900 (16 ft 1 in) |

| Track Length On Ground, mm (ft/in) | 3810 (12 ft 6 in) |

| Tailswing Radius, mm (ft/in) | 3180 (10 ft 5 in) |

| Ground Clearance, mm (ft/in) | 747 (2 ft 5 in) |

| Superstructure Width, mm (ft/in) | 3200 (10 ft 6 in) |

| Slewing Angle, Degrees | 360 |

| Cab Leveling tilt (Forward), Degrees | 26 |

| Cab Leveling tilt (Rear), Degrees | 14 |

| Cab Leveling tilt (Side), ± Degrees | 7 |

CAPACITIES

| Fuel Tank, ltr (gallons (US)) | 1080 (285) |

|---|---|

| Number of Alternators | 2 |

| Alternator Output, Amp | 100 |

PERFORMANCE

| Slew Speed, rpm | 4.8 |

|---|---|

| Travel Speed, kph (mph) | 3.6 (2.2) |

| Reference Harvesting Head | Waratah HTH624C |

| Felling Diameter, mm (inches) | 810 (31.9) |

| Delimbing Diameter, mm (inches) | 760 (29.9) |

| Cutting Radius - Maximum, mm (ft/in) | 9120 (29 ft 11 in) |

| Cutting Radius - Minimum, mm (ft/in) | 3680 (12 ft 1 in) |

| Cutting Swath Horizontal, mm (ft/in) | 5440 (17 ft 10 in) |

| System Voltage, V | 24 |

| Main Pump | Axial Piston |

| Pump Flow, lt/min (gallons (US) / min) | 532 (141) |

WEIGHTS

| Operating Weight, kg (lbs) | 40914 (92916) |

|---|---|

| Weight - With Reference Head, kg (lbs) | 40914 (92916) |

| Weight - Without Reference Head, kg (lbs) | 37454 (85286) |

Contact Us

-

325 Walt Messick Road

Harrington, Delaware 19952

Phone: (302) 398-3729

Toll Free: (800) 237-1272