-

Menu -

Locations -

Search

John Deere 437E Knuckleboom Loader

Double tap to zoom

437E Knuckleboom Loader

Knuckleboom Loaders

Overview:

- Gross Rated Power: 129 kW (173 hp) at 2,000 rpm

- Boom Reach: 9754 mm (32 ft. 0 in.)

- Operating Weight: 15 909 kg (35,073 lb.)

- Lift Capacity: 11 730 kg (25,860 lb.)

Get A Quote

Fields with asterisks* are required. Please email our helpful staff with any questions or comments using the contact form.

Loan Calculator

Use the Loan Calculator to help you determine the financing and payment options that are best for you.

**The accuracy of this calculator and its applicability to your circumstances is not guaranteed. You should obtain personal advice from qualified professionals. This information is provided for illustrative purposes only and does not constitute an application. This notice does not guarantee loan approval, nor is it an offer or commitment to make a loan to you on the above terms.

Send To A Friend

Fields with asterisks* are required. Your friend will receive an email that contains a reference to this page. Please send this email only to people you know who would be interested in this information.

Share This Product:

Features

Maximize comfort and visibility with a spacious cab

Redesigned cab-window on a 437E

Redesigned cab-window on a 437E

Operator station on a 437E

Operator station on a 437E

By maximizing comfort and visibility, you can spend more time focusing on the task at hand, while feeling less fatigued at the end of the day.

- The redesigned cab-window removes the need for an external barrier, which improves forward visibility while also maintaining operator-protection requirements

- A lower hood profile opens up the view to the left-rear side of the machine

- The large doorway and spacious cab allow for easy entry and exit

- Enhanced ventilation and a fully adjustable seat keep you comfortable on long days

- Premium stereo options including satellite-ready radio, Bluetooth® pairing, and a cell phone mount, give you ultimate media control

Bluetooth is a trademark of Bluetooth SIG, Inc.

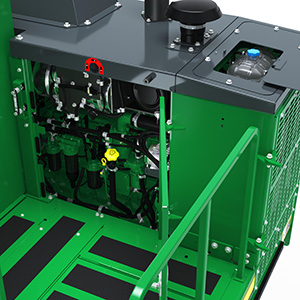

Increase uptime with easy access to daily service points

Access to daily service points on a 437E

Access to daily service points on a 437E

Fuel and diesel exhaust fluid (DEF) fill locations on a 437E

Fuel and diesel exhaust fluid (DEF) fill locations on a 437E

Swing-out cooler doors on a 437E

Swing-out cooler doors on a 437E

Daily service points can easily be accessed from the operator’s platform; reducing the time and effort needed to check each service point.

- Hinged panels allow quick and easy access to the necessary service points in the engine compartment

- Fuel and diesel exhaust fluid (DEF) fills are located on the same side of the machine

- Battery disconnect switch is conveniently located on the operator platform

- Swing-out cooler doors provide easy access to the coolers for cleanouts

- Hydraulic oil drain, fill pump, and filter can all be accessed from ground level

- Electric hydraulic fluid fill pump reduces fill time

- Hydraulic oil reservoir sight gauge is visible from the operator’s seat

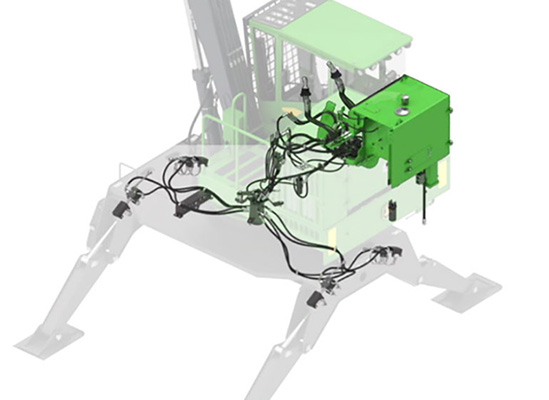

Efficient hydraulics

Hydraulic system for a 337E and 437E

Hydraulic system for a 337E and 437E

Proven pressure-compensated load-sensing hydraulic system delivers power on demand for strong delimbing and loading performance, while minimizing hydraulic heat generation and reducing fuel consumption.

- Dedicated swing circuit provides the power needed for delimbing and loading tasks

- A second hydraulic oil filter doubles the change interval to 2,000 hours

- An optional vacuum pump helps reduce oil loss during an unexpected downtime event or when servicing hydraulic components

- Hydraulic options for the 437E allow you to power a circle saw and/or a self-propelled carrier

- The circle saw’s dedicated pump increases cutting power and saw-recovery time

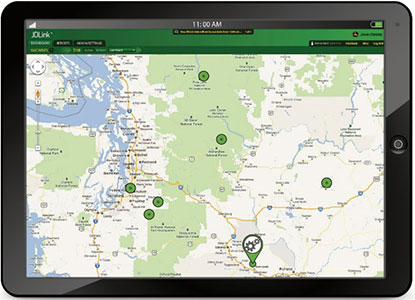

Gain valuable insights with Precision Forestry solutions

Mobile device using JDLink™

Mobile device using JDLink™

TimberMatic™ Maps monitor displaying live production data

TimberMatic™ Maps monitor displaying live production data

Machine Health Monitoring Center

Machine Health Monitoring Center

Now included in base machine, the JDLink telematic system provides the foundation for John Deere’s Precision Forestry solutions. These systems help optimize your machine, your uptime, and your jobsites, which ultimately lead to improved productivity.

- JDLink connectivity enables you to view several parameters of your machine, including its location, fuel level, average fuel burn rate, idle time, machine utilization, and much more

- John Deere Connected Support™ allows the dealer to provide remote diagnostics, rapid service response with the right part in hand, and parts availability; all to maximize machine uptime

- John Deere’s centralized Machine Health Monitoring Center analyzes data from thousands of connected machines, identifies trends, and develops recommended actions to help prevent downtime

- Optional TimberMatic Maps gives enhanced visibility to the jobsite, which streamlines communication and increases efficiency

- TimberManager™ provides remote visibility to your operation from any device, allowing you to make smart business decisions based on real-time production data

Specifications

DRIVELINE

| Engine Manufacturer | John Deere |

|---|---|

| Engine Model | 6068 HTJ57 PowerTech PVS |

| Displacement, ltr (Inches³) | 6.8 (415) |

| Rated Speed, rpm | 2000 |

| Engine Output - Net, kW (hp) | 119 (159) |

| Engine Output - Gross, kW (hp) | 129 (173) |

| Engine Torque, Nm (lbf / ft) | 750 (553.1) |

| Torque Rise, % | 21 |

DIMENSIONS

| Base Carrier Length, m (ft/in) | 3.81 (12 ft 6 in) |

|---|---|

| Height Over Cab, mm (ft/in) | 4112 (13 ft 6 in) |

| Stabilizer Footprint Length, m (ft/in) | 3.81 (12 ft 6 in) |

| Superstructure Width, mm (ft/in) | 2606 (8 ft 7 in) |

| Boom Horizontal Reach, m (ft/in) | 9.754 (32 ft ) |

| Slewing Angle, Degrees | 360 |

CAPACITIES

| Fuel Tank, ltr (gallons (US)) | 340 (90) |

|---|---|

| Hydraulic Tank, ltr (gallons (US)) | 151 (40) |

| Alternator Output, Amp | 200 |

PERFORMANCE

| Slew Speed, rpm | 10 |

|---|---|

| 5ft lift @ 10ft radius, kg (lbs) | 6180 (13625) |

| 5ft lift @ 15ft radius, kg (lbs) | 11730 (25860) |

| 5ft lift @ 20ft radius, kg (lbs) | 8690 (19158) |

| 5ft lift @ 25ft radius, kg (lbs) | 6950 (15322) |

| 5ft lift @ 30ft radius, kg (lbs) | 5570 (12280) |

| 10ft lift @ 10ft radius, kg (lbs) | 8980 (19798) |

| 10ft lift @ 15ft radius, kg (lbs) | 10500 (23149) |

| 10ft lift @ 20ft radius, kg (lbs) | 8160 (17990) |

| 10ft lift @ 25ft radius, kg (lbs) | 6780 (14947) |

| 10ft lift @ 30ft radius, kg (lbs) | 5710 (12588) |

| System Voltage, V | 12 |

| Pump | Axial Piston |

WEIGHTS

| Operating Weight, kg (lbs) | 15909 (35073) |

|---|

Contact Us

-

325 Walt Messick Road

Harrington, Delaware 19952

Phone: (302) 398-3729

Toll Free: (800) 237-1272