-

Menu -

Locations -

Search

John Deere 750L Dozer

750L Dozer

Mid-Size Dozers

Overview:

- Net Power: 131 kW (175 hp) at 1,700 rpm

- Operating Weight: 17 041-18 162 kg (37,569-40,040 lb.)

- Track on Ground: 2604-3093 mm (103-122 in.)

Get A Quote

Fields with asterisks* are required. Please email our helpful staff with any questions or comments using the contact form.

Loan Calculator

Use the Loan Calculator to help you determine the financing and payment options that are best for you.

**The accuracy of this calculator and its applicability to your circumstances is not guaranteed. You should obtain personal advice from qualified professionals. This information is provided for illustrative purposes only and does not constitute an application. This notice does not guarantee loan approval, nor is it an offer or commitment to make a loan to you on the above terms.

Send To A Friend

Fields with asterisks* are required. Your friend will receive an email that contains a reference to this page. Please send this email only to people you know who would be interested in this information.

Share This Product:

Features

Make long days feel shorter with the most comfortable cab available

John Deere 750L dozer cab interior

John Deere 750L dozer cab interior

John Deere 750L cab with optional premium seat

John Deere 750L cab with optional premium seat

Looking for ways to retain skilled operators? All L-Series dozers provide a quiet, comfortable ride with precise control, and convenience that is even better than previous John Deere cabs. Operators will appreciate improved visibility with clear sight lines to the blade corners and around the machine.

- Get unmatched visibility - The 750L has a 14 percent larger operator station focused on enhanced visibility and comfort. The updated cab also has 10 percent more glass area, 13 percent larger doors, and a streamlined hood profile, providing exceptional visibility to the blade and jobsite.

- Premium cab options – Long days won’t seem so long with the leather-accented air suspension seat with heat and ventilation or the automatic temperature control HVAC system. Improve situational awareness with the rearview camera.

- Re-designed joysticks – New ergonomic joystick grips fit comfortably in the operators’ hands and include proportional blade angle control. Hydraulic response is customizable and can be fine-tuned to match the application and operator preference.

Uptime and reliability are key

John Deere 750L Dozer

John Deere 750L Dozer

Uptime on a jobsite isn’t demanded, it’s expected. Ensuring you have reliable equipment, and the support of your local John Deere dealer is important. A key focus on John Deere’s L-Series dozers is to advance reliability and improve uptime of our machines.

- Efficiently routed – The redesigned mainframe of the 750L optimizes hose and harness routings for hydraulic and electrical components. This reduces harness and hose rub points to keep your machine running longer.

- Unbeatable service access – The 750L features large service door openings for easy access to periodic maintenance points and main components.

- Keep daily maintenance simple – Enjoy easy access to all daily maintenance checks. A periodic maintenance chart is also located inside the rear service door. This color-coded chart displays maintenance intervals and refill capacities for maintenance items.

Move more yards, more efficiently

John Deere 750L Dozer

John Deere 750L Dozer

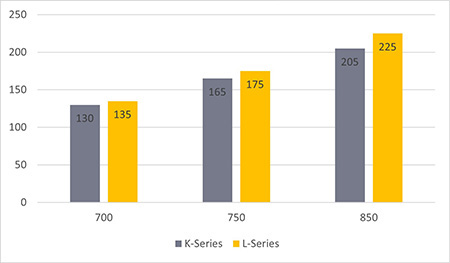

You want the ability to move more yards of material per gallon of fuel burned, even in the toughest conditions. With L-Series crawlers, increased horsepower boosts efficiency, allowing the operator to move more material per pass and cover more area throughout the workday.

- More horsepower means more pushing power - The horsepower of the 750L was increased to 175HP, compared to the previous series

- No increase in fuel consumption - Even with the added horsepower, the 750L’s fuel consumption was kept comparable to the fuel consumption of the previous series

Horsepower (Y-axis) comparison of K-Series and L-Series Dozers (X-axis)

Horsepower (Y-axis) comparison of K-Series and L-Series Dozers (X-axis)

Reliable, easy, and customizable

John Deere 750L Dozer

John Deere 750L Dozer

The John Deere hydrostatic system makes operation simple and gives you the confidence to conquer any task. For unmatched durability, each track has its own independent hydrostatic pump and motor while the blade and ripper functions have their own independent hydraulic pump. This system allows you to tailor both transmission and hydraulic operating characteristics to your desired preference.

- Constant power to both tracks - Allows operators to carry heavy loads through turns and counter-rotate both while in gear and in neutral.

- Don’t sacrifice performance - The operator can independently control hydraulic and transmission functions without sacrificing hydraulic speed.

- More work, less service - Hydraulic and hydrostatic oil change intervals have doubled from the previous series, now 4,000 hours.

Precise technology options to conveniently meet specifications

John Deere 750L Dozer with SmartGrade technology

John Deere 750L Dozer with SmartGrade technology

John Deere SmartGrade display

John Deere SmartGrade display

Looking for a return on your investment? Look no further. John Deere L-Series dozers have technology options that will increase productivity, allowing you to get to grade faster with fewer passes. John Deere precision construction technology enables operators to make accurate grading passes while significantly reducing re-work. The best part? Our machine technology can be upgraded at any time, from entry-level to advanced, know you have the flexibility to upgrade when the time is right.

- Standard EH Controls – makes it feasible to add on any kind of grade control system

- Slope Control – An entry-level grade control system that assists operators in grading smooth, planer surfaces. Slope control allows the operator to view and set blade slope while the system automatically controls the blade to maintain the desired slope. This technology enables an easy upgrade path to a SmartGrade system. Slope Control can be installed via upgrade kit on all existing L-Series dozers.

- SmartGrade™ - John Deere’s fully integrated 3D GNSS grade control system. SmartGrade integrates harnesses and components into the machine for added convenience, making external masts or harnesses a thing of the past. The enhanced feature set of Auto SmartGrade enables novice operators to push more material each pass. SmartGrade can be installed via upgrade kit on all existing L-Series dozers.

- SmartGrade Remote Support – New to SmartGrade? Looking for improved support capabilities? L-Series SmartGrade dozers come standard equipped with both remote display access and wireless data transfer. Grant support access to anyone within your company or local dealer.

- Remote Display Access – Remotely view and control the SmartGrade display to easily troubleshoot issues and train operators.

- Wireless Data Transfer – Wirelessly transfer files such as project files and updates to 3D models both to and from the machine.

- SmartGrade Remote Support – New to SmartGrade? Looking for improved support capabilities? L-Series SmartGrade dozers come standard equipped with both remote display access and wireless data transfer. Grant support access to anyone within your company or local dealer.

|

450 |

550 |

650 |

700 |

750 |

850 |

950 |

Slope Control (optional) |

X |

X |

X |

X |

X |

X |

|

SmartGrade (optional) |

|

|

X |

X |

X |

X |

X |

Slope Control and SmartGrade model availability

*Slope Control and SmartGrade™ options are only available with PAT blade configurations.

Specifications

DRIVELINE

| Engine Manufacturer | John Deere |

|---|---|

| Engine Model | PowerTech PVS 6068 |

| Displacement, ltr (Inches³) | 6.8 (414) |

| Rated Speed, rpm | 1800 |

| Engine Output - Net, kW (hp) | 131 (175) |

| Transmission Type | Hydrostatic |

| Speeds Mode 1 - Forward | 1 |

| Speeds Mode 1 - Reverse | 1 |

| Final Drive | Triple Reduction |

| Track Rollers | 7 |

| Shoe - Pitch, mm (inches) | 191 (7.5) |

| Shoe - Type | Single Grouser - Moderate Service |

| Ground Contact Area, cm² (Inches²) | 35677 (5530) |

| Number Of Shoes | 40 |

DIMENSIONS

| Height - Max, mm (ft/in) | 3343 (11 ft 6 in) |

|---|---|

| Ground Clearance, mm (inches) | 358 (14) |

| Track Length - On Ground, mm (ft/in) | 2604 (8 ft 7 in) |

| Track Gauge, mm (ft/in) | 1880 (6 ft 2 in) |

| Blade - Width, mm (ft/in) | 3265 (10 ft 9 in) |

| Blade - Dig Depth, mm (inches) | 594 (23.4) |

| Blade - Tilt, mm (ft/in) | 681 (2 ft 3 in) |

CAPACITIES

| Fuel Tank, ltr (gallons (US)) | 370 (97.7) |

|---|---|

| Hydraulic Tank, ltr (gallons (US)) | 98 (25.9) |

| Blade - Capacity, m³ (yd³) | 4.3 (5.6) |

PERFORMANCE

| Speed - Forward Maximum, kph (mph) | 9.7 (6) |

|---|---|

| Speed - Reverse Maximum, kph (mph) | 9.7 (6) |

| Ground Bearing Pressure, kPa (PSI) | 47.8 (6.93) |

| Implement Pump - Type | Piston |

| Implement Pump - Flow, lt/min (gallons (US) / min) | 130 (34) |

| Implement Pump - Pressure, bar (PSI) | 249.93 (3625) |

WEIGHTS

| Operating Weight, kg (lbs) | 17386 (38330) |

|---|

Contact Us

-

325 Walt Messick Road

Harrington, Delaware 19952

Phone: (302) 398-3729

Toll Free: (800) 237-1272