Features

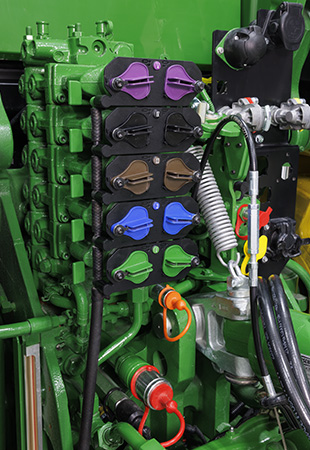

Improved Selection Control Valve (SCV) configurations

Reactive steering provides an automotive-like experience

Experience the ultimate in comfort with the Ultimate Comfort and Convenience package

7 and 8 Series Visibility packages let you run with confidence, dawn until dusk

Efficiency and comfort in the palm of your hand using CommandPRO™ control

Maximize versatility with front hitch options that fit a variety of applications

Increase productivity with John Deere integrated solutions

Specifications

Key Specs

| Engine description | John Deere PowerTech™ (B20 diesel compatible) 9.0L |

|---|---|

| Engine displacement | 9.0 L 549 cu in. |

| Rated engine power | ECE-R120: 243 kW 330 hp |

| Maximum engine power | ECE-R120: 267 kW 363 hp |

| Rated PTO power (hp SAE) | 193.9 kW 260 hp |

| Maximum PTO power | |

| Transmission type | Standard: John Deere e23™ 42 km/h 26 mph Optional: John Deere e23 transmission 50 km/h 31 mph John Deere Infinitely Variable Transmission (IVT™) 0.050-42 km/h (0.030-26 mph) John Deere Infinitely Variable Transmission (IVT) 0.050-50 km/h (0.030- 31 mph) |

| Hydraulic pump rated output | Standard: 63 cc: 162 L/min 43 gpm Optional: 85 cc: 222.3 L/min 59 gpm |

| Rear hitch category (SAE designation) | Standard: Category 3N/3 with Quik-Coupler Optional: Category 3/3N with hook ends Category 3N/3 with hook ends |

| Base machine weight | e23, TLS™, 18.4R46: 10,000 kg 22,000 lb |

| Maximum engine power PS (hp ISO) at max engine speed (EU 2016/1628) | |

| Rated engine power PS (hp ISO) at rated engine speed (EU 2016/1628) |

Engine specifications

| Description | John Deere PowerTech™ (B20 diesel compatible) 9.0L |

|---|---|

| Engine type | Diesel, in-line, 6-cylinder, wet-sleeve cylinder liners with 4 valves in head |

| Engine family | MJDXL09.0319 |

| Rated speed | 2100 rpm |

| Aspiration | Single turbocharger, variable geometry turbo |

| Cylinders liners | |

| Emission level | Final Tier 4 |

| After treatment type | Diesel oxidation catalyst (DOC)/diesel particulate filter (DPF) |

| Displacement | 9.0 L 549 cu in. |

Engine performance

| Rated power | ECE-R120: 243 kW 330 hp |

|---|---|

| Rated PTO power (hp SAE) | 193 kW 260 hp |

| Maximum PTO power | |

| Intelligent Power Management (IPM) | |

| Power boost | IPM: 27 kW 30 hp |

| Maximum engine power | ECE-R120: 267 kW 363 hp |

| Engine peak torque | At 1600 rpm: 1,545 Nm 1,139 lb-ft |

| Drawbar power | |

| PTO torque rise | 40 percent |

| Fuel injection system and control | |

| Air cleaner type | |

| Maximum engine power PS (hp ISO) at max engine speed (EU 2016/1628) | |

| Rated engine power PS (hp ISO) at rated engine speed (EU 2016/1628) |

Transmission

| Type | Standard: John Deere e23™ 42 km/h 26 mph Optional: John Deere e23 transmission 50 K 31 mph John Deere Infinitely Variable Transmission (IVT™) 0.050-42 km/h (0.030-26 mph) John Deere Infinitely Variable Transmission (IVT) 0.050-50 km/h (0.030- 31 mph) |

|---|---|

| Reverser | |

| Clutch; wet/dry | |

| Creeper |

Hydraulic system

| Type | Closed-center, pressure/flow compensated system with load sensing |

|---|---|

| Pump rated output | Standard: 63 cc: 162 L/min 43 gpm Optional: 85 cc: 222.3 L/min 59 gpm |

| Available flow at a single rear SCV | 132 L/min 35 gpm |

| Available flow at front SCVs | 126 L/min 33 gpm |

| Number of rear selective control valves (SCVs) | Standard: Four SCVs Optional: Three to six ISO couplers: 12.7 mm 1/2 in. Five ISO couplers (SCV 1: 19-mm [3/4-in.] couplers, SCV 2-5: 12.7-mm [1/2-in.] coupler) |

| Number of mid selective control valves (SCVs) | |

| Number of front selective control valves (SCVs) | One with front hitch |

| Joystick SCV control | |

| Auxiliary hydraulic features | |

| SCV control | Electronic |

Rear hitch

| Hitch draft control load sense type | |

|---|---|

| Remote control valves available | |

| Hitch category (SAE designation) | Standard: Category 3N/3 with Quik-Coupler Optional: Category 3/3N with hook ends Category 3N/3 with hook ends |

| Maximum lift capacity behind lift points | Standard (Category 3): 6,894 kg 15,200 lb Optional (Category 3N): 7,847 kg 17,300 lb Standard (Category 3 with hook ends): 6,894 kg Optional (Category 3N with hook ends): 7,847 kg |

| Lift capacity at standard frame | |

| Sensing type | Electrohydraulic |

| Rear axle differential lock |

Drawbar

| Drawbar category | Standard: Category 4 |

|---|---|

| Maximum vertical load | Standard: Category 3: 1,837 kg 4,050 lb Optional: Category 3 with heavy-duty support: 4,536 kg 10,000 lb |

Rear power take-off (PTO)

| Type | Independent Standard: 44.45 mm (1.75 in.) 20-spline, 1,000 rpm Optional: 44.45 mm (1.75 in.), 20-spline, 1,000 rpm capable of 35 mm (1.375 in.) 540/1000 rpm 44.45 mm (1.75 in.) 20-spline, 1000 rpm with 35-mm (1.375-in.) 540E/1000/1000E rpm gearcase 44.45 mm (1.75 in.) 20-spline, 1000 rpm with 35-mm (1.375-in.) 540/540E/1000 rpm gearcase |

|---|---|

| Engine rpm (at rated PTO speeds) | 540/1000 PTO rpm at 1950 engine rpm 540E/1000E PTO rpm at 1750 engine rpm |

| Economy PTO speeds | |

| Reverse PTO speeds | |

| Multispeed PTO option availability | |

| Ground speed PTO option availability | |

| PTO actuation | Electric switch with adjustable modulation |

Front hitch

| Category | Category 3N, ground engaging |

|---|---|

| Electric power | Seven-pin connector |

| Standard lift capacity | 5,200 kg 11,464 lb |

| Front power take-off (PTO) | Available: 35 mm (1.375 in.) 21 spline, 1,000 rpm, counter-clockwise rotation (when facing PTO) Available through Parts: 44.45 mm (1.75 in.), 20 spline, 1,000 rpm, counter-clockwise rotation (when facing PTO) |

| PTO speed | 1,000 PTO rpm at 1940 engine rpm |

Rear axle

| Type | Standard: Rack-and-pinion or flange axles Optional: Diameter: 110 x 2550 mm 4.33 x 100.4 in. Diameter: 110 x 3010 mm 4.33 x 118.5 in. Diameter: 120 x 2550 mm 4.72 x 100.4 in. Diameter: 120 x 3010 mm 4.72 x 118.5 in. Flanged axle: 335 mm (13.2 in.) |

|---|---|

| Final drive type | Inboard planetary three pinion |

| Differential controls | |

| Axle type | |

| Brakes, type and control | |

| Rear differential lock | Full-locking electrohydraulic |

| Load rating |

Front axle

| Type | Standard: 1300 Series MFWD: tread range 1524 to 2235 mm 60 to 88 in. Optional: TLS: Tread range 1524 to 2235 mm TLS with front brakes available with 40 km/h 24.9 mph TLS with front brakes standard with 50 km/h 31 mph |

|---|---|

| Front axle differential lock | 1300 Series MFWD: Limited slip TLS: Limited slip TLS with front brakes: Full-locking electrohydraulic (actuated at same time as rear diff lock) |

| Load rating |

Tires

| Rear | RCI Group 48/49 |

|---|---|

| Wheel tread range | |

| Turning radius with brakes | 600/70R30 group 43 tires at 188.2-cm (74.1-in.) spacing, TLS: 6.7 m 22 ft 620/75R30 group 44 tires at 208.3-cm (82-in.) spacing, TLS: 8.7 m 28.5 ft |

| Turning radius without brakes | |

| Central Tire Inflation System (CTIS) | |

| Front |

Tracks

| Tread spacing | |

|---|---|

| Drive type | |

| Track width | |

| Mid-rollers |

Steering

| Type | Standard: Hydraulic power-steering with electric pump back-up Optional: ActiveCommand Steering 2 (ACS2) w/ electronic back-up pump |

|---|

Brakes

| Primary brake (foot brake) | |

|---|---|

| Secondary brake | |

| Park lock | |

| MFWD braking | |

| Front axle brakes | |

| Auxiliary brakes | |

| Hydraulic trailer brakes | |

| Pneumatic trailer brakes |

Electrical system

| Alternator size | Standard: 210 amp Optional: 250 amp |

|---|---|

| Battery options | 12 V |

| Working lights | Standard: 18 halogen Available: 18 LED or 22 LED |

| Type of bulb in headlight (Halogen, Zenon, LED) | Standard: 65-W halogen Available: LED |

| Type of bulb in beacon (Halogen, Zenon, LED) | |

| dB(A) rating for backup alarm | |

| Total cold cranking amps | With two 925 CCA group 31 batteries: 1850 CCA |

Operator station

| Rollover protective structure, OOS | |

|---|---|

| Seat | Degree of seat swivel, left hand Optional: 25 degree Degree of seat swivel, right hand 40 degree Standard: air suspension Optional: ActiveSeat™ II |

| Cab suspension | Optional |

| Instructional seat | Standard |

| Display | Standard: 4100 Generation 4 CommandCenter™: 25.4 cm 10 in. |

| Radio | Standard: AM/FM stereo with weatherband, remote controls, auxiliary input jack, four speakers and external antenna |

| Inner cab volume | 3.24 m3 114 cu ft |

| dB(A) rating | |

| Cab glass area | 6.56 m2 70.61 sq ft |

| Safety glass rating | |

| Front visibility |

Dimensions

| Wheelbase | 2,925 mm 115.2 in. |

|---|---|

| Overall width | |

| Overall length | 5,540 mm 218 in. |

| Overall height | |

| Drawbar clearance | Group 48 rear tires: 415 mm 16.3 in. Group 49 rear tires: 461 mm 18.1 in. |

| Front axle center | |

| Approximate shipping weight, Open;Cab |

Weight

| Base machine weight | e23, TLS, 18.4R46: 10,000 kg 22,000 lb |

|---|---|

| Maximum ballast level | SAE PTO hp: 61.2 kg 135 lb |

| Maximum permissible weight |

Capacities

| Crankcase oil volume | 23 L 6.1 U.S. gal. |

|---|---|

| Fuel tank | e23™: 463 L 122 U.S. gal. IVT: 513 L 135 U.S. gal. |

| Diesel exhaust fluid (DEF) tank | 26.2 L 6.9 U.S. gal. |

| Cooling system | 44.5 L 11.8 U.S. gal. |

| Transmission-hydraulic system | 160 L 42.3 U.S. gal. |

Serviceability

| Interval for engine oil change | 500 hours |

|---|---|

| Interval for hydraulic/transmission oil change | 1,500 hours |

| Interval for engine coolant change | 6,000 hours |

Loaders

| Loader | 700M |

|---|---|

| Lift capacity at full height | 2,417 kg 5,304 lb |

| Maximum lift height | 4,741 mm 186 in. |

| Leveling type |

Precision AG

| Guidance | Integrated AutoTrac™ |

|---|---|

| Telematic | JDLink™ |

| Remote diagnostics | ServiceADVISOR™ Remote: available with JDLink hardware and activations Remote Display Access: available with JDLink hardware and activations |

Miscellaneous

| AutoTrac ready | |

|---|---|

| ISOBUS ready | |

| CommandCenter video inputs | |

| Immobilizer | |

| Side slope rating | |

| Uphill/downhill slope rating | |

| Country of manufacture | USA |

Additional information

| Date collected | 10-Jul-2020 |

|---|