-

Menu -

Locations -

Search

John Deere John Deere HarvestLab™ 3000 for S700 Series Combines

Double tap to zoom

John Deere HarvestLab™ 3000 for S700 Series Combines

Data Management

Overview:

- On-the-go measuring of moisture, protein, starch

and oil values in wheat, barley and rapeseed/canola

- Available as a dealer kit for S700 Series

Combines (MY18 and newer)

- View your data in the combine or in the John Deere Operations Center™

- Know how much nitrogen was removed and where it is needed to sustainably optimize yield for next year’s crop

Get A Quote

Fields with asterisks* are required. Please email our helpful staff with any questions or comments using the contact form.

Loan Calculator

Use the Loan Calculator to help you determine the financing and payment options that are best for you.

**The accuracy of this calculator and its applicability to your circumstances is not guaranteed. You should obtain personal advice from qualified professionals. This information is provided for illustrative purposes only and does not constitute an application. This notice does not guarantee loan approval, nor is it an offer or commitment to make a loan to you on the above terms.

Send To A Friend

Fields with asterisks* are required. Your friend will receive an email that contains a reference to this page. Please send this email only to people you know who would be interested in this information.

Share This Product:

Features

Quick overview: Real-time protein and oil measurements

Realtime constituent information during harvest on the Gen 4/G5 combine display

Realtime constituent information during harvest on the Gen 4/G5 combine display

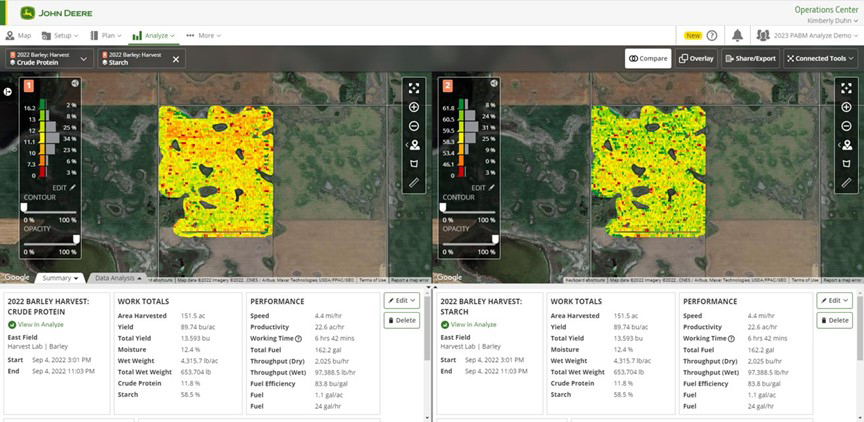

Know your protein, get paid for your protein. The HarvestLab™ 3000 Grain Sensing solution enables customers to measure constituents like protein and oil in real-time during harvest. Every second the grain sensing system records and maps small grains moisture, protein, starch and oil as it is harvested. This information can be viewed in the combine, allowing you to make grain marketing decisions on-the-go, or in the John Deere Operations Center™. After your work is finished, utilize the Operations Center to view and analyze your work. This will allow you to:

- Know your protein and yield to accurately know how much nitrogen was removed and replace how much is needed, where it is needed, to sustainably optimize the yield for next year’s crop. This directly equates to per acre profit potential. Furthermore, this technology allows small grains farmers to reduce input costs and/or maximize yield and protein through better nutrient management or variety choice, by simply targeting points of the field where high-protein grain was harvested or focus on areas which didn’t reach the quality and/or yield targets.

- Increase profit per bushel of grain for high quality protein, starch or oil content. By knowing the constituent value of their grains, this solution enables producers to market their grain for the highest potential return at their local elevator and take advantage of premiums for constituent values like protein, starch and oil.

These benefits can be unlocked for the crops and constituents as part of a separate Grain Sensing Calibration:

| Wheat | Barley | Canola | Corn | Soybeans |

| Moisture | Moisture | Moisture | Moisture | Moisture |

| Protein | Protein | Protein | Protein | Protein |

| Starch | Starch | Oil | Starch | Oil |

Yield and Protein map shown in Operations Center

Yield and Protein map shown in Operations Center

Fully integrated on the combine and Operations Center

Grain Sensing is fully machine integrated and connected to Operations Center

Grain Sensing is fully machine integrated and connected to Operations Center

Grain Sensing is fully integrated on our John Deere S700 series combines, allowing it to work seamlessly together with other components like the StarFire™ receiver and Gen4 display to enable site-specific documentation of the constituents and yield. This results in the following benefits:

- One constituent value each second for high accuracy resolution maps

- Easy work setup and documentation, reducing data loss

- No additional (third party) displays needed

- Automatic and near real-time flow to Operations Center when JDLink™ is enabled

Fully integrated on the clean grain elevator and plugged in the combine harness

Fully integrated on the clean grain elevator and plugged in the combine harness

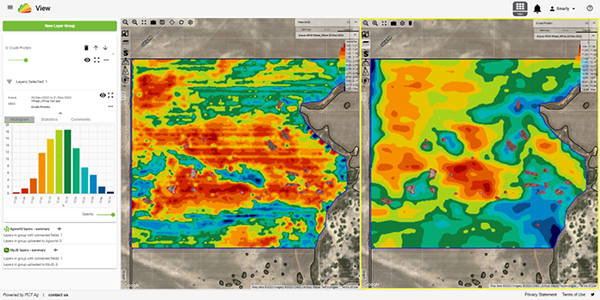

Improve grain production with PCT Agcloud

PCT Agcloud map shows a yield map (left) and protein map (right) that was shared through an API with John Deere Operations Center

PCT Agcloud map shows a yield map (left) and protein map (right) that was shared through an API with John Deere Operations Center

Utilize PCT Agcloud to close the gap in nitrogen management. Knowing your protein and yield to accurately know how much nitrogen was removed and replace how much is needed, where it is needed, to sustainably optimize the yield for next year’s crop. Getting the most out of your yield and protein data is crucial when maximizing the value of Grain Sensing, and a paid partnership with PCT Agcloud will benefit the producer with the following:

- Automated creation of nitrogen removal and product replacement when soil tests are available

- Automated cleaning, editing and intersecting zone creation

- Quick prescription creation and adjustments with prescriptions sent straight to your machine (nitrogen Rx or any other nutrient)

- Manage protein and yield to optimize land capability and Nitrogen Use Efficiency (NUE)

- Increase grain quality (higher protein/oil)

The nitrogen removal capabilities of a paid subscription with PCT Agcloud are not yet available in the John Deere Operations Center. Therefore, a dealer partnership with PCT Agcloud is strongly encouraged to further unlock the value of Grain Sensing for the customer.

Get the best price paid for your grains

Real-time analysis of the quality of your wheat, barley, canola, corn or soybeans

Real-time analysis of the quality of your wheat, barley, canola, corn or soybeans

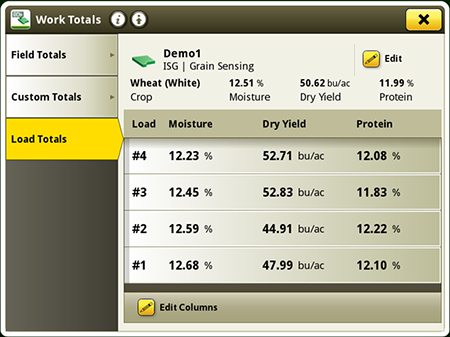

Grain Sensing enables to monitor in real-time the quality (protein, starch or oil) of the grain during harvest. The combine operator can utilize the instant readings and work totals on the Gen4/G5 display, whereas the farm manger or owner can simultaneously monitor the harvest progress via the Operations Center. This will bring the following benefits:

- Be more confident when selling your grain to your local elevator. Know your quality upfront and earn the greatest premium for grain in your area or overcome penalties for not reaching the criteria.

- Use the load and field totals on the Gen4/G5 display to segregate low and high-quality grain in different trailers or bins for the optimized selling of your grain.

- Blend different qualities of grain (for example low and high protein wheat) to meet the criteria of the grain buyer.

- Send trailers and trucks to the right destination to best fit your grain contracts to get the best price out of the grain using Operations Center mobile or work totals on Gen4/G5.

- No need to wait on lab analysis or reference analysis at the grain buyer.

Monitor in real-time your load and field average on the Gen4 display to decide during harvest where to unload the combine grain tank

Monitor in real-time your load and field average on the Gen4 display to decide during harvest where to unload the combine grain tank

Grain Sensing enables farmers to be the first to know the quality of their grain, and market it to the highest bid accordingly. In reality, various elevators and grain terminals could be miles in different directions. With Grain Sensing, the farmer can shop his grain around to the highest bidder. With grain sensing you ensure no valuable time and fuel is wasted by sending trucks to the wrong delivery location.

One sensor, four applications

The HarvestLab™ 3000 sensor can be used for the following four different applications:

- Grain Sensing on John Deere combines

- Moisture and constituents sensing on John Deere self-propelled forage harvesters (SPFH)

- Stationary use with a turntable

- Manure Sensing on slurry applicators

Grain Sensing on John Deere combines

HarvestLab 3000 on a combine

HarvestLab 3000 on a combine

The latest use case of the HarvestLab 3000 is on S700 series combines where it enables high quality readings of constituents like protein, starch and oil in grain. The measurements are documented on the Gen 4/G5 display and automatically synced with the Operations Center using JDLink. Grain Sensing helps farmers improve the nutrient management, production and marketing of their grain.

- Real-time constituent measurements during grain harvest

- Improved production of grains through nutrient management, variety selection and validation of machine performance

- Greater profitability per bushel through informed marketing of grains: know your protein, get paid for your protein

Moisture and Constituent Sensing on John Deere SPFHs

HarvestLab 3000 on an SPFH

HarvestLab 3000 on an SPFH

The HarvestLab 3000 sensor enables an accurate measurement and documentation of dry matter and constituents*, like starch and protein, for different crop types. For better fertilization planning in the next season, operators can use the HarvestLab 3000 sensor to determine and document the nutrient level which was taken off the field during harvest. It also helps to achieve higher quality forage by enabling automatic length-of–cut adjustments on-the-go to ensure optimal bunker compaction and conservation. In addition, the smart use of additives ultimately leads to higher milk yields and more efficient use of feed.

- Yield measurements and documentation during harvesting

- Moisture, dry matter, and constituent* (like protein, starch, fiber, neutral detergent fiber, acid detergent fiber, ash and sugar) analysis on-the-go

- Biogas producers or livestock farmers get accurate information on the actual crop they buy

- Inoculant dosing based on current dry matter level

- Automatic length-of-cut adjustment on-the-go based on current dry matter level

*NOTE: Constituent measurements are only available with an additional purchased grass or corn calibration. The measured constituents, like protein and starch, depend on the purchased calibration.

Stationary use with a turntable

HarvestLab 3000 equipped with the stationary kit (turntable, glass bowl and ethernet cable) and connected to a computer

HarvestLab 3000 equipped with the stationary kit (turntable, glass bowl and ethernet cable) and connected to a computer

The HarvestLab 3000 sensor and stationary kit can provide time and cost savings with use in the barn, field office, or anywhere feed analysis is needed. For example, the components of a total mix ratio (TMR) can be measured every day to ensure the correct mix ration to achieve maximum milk yield.

- Monitors silage quality all year long

- Supports daily feed ration calculation

- Moisture, dry matter, and constituent* (like protein, starch, fiber, neutral detergent fiber, acid detergent fiber, ash, and sugar) analysis within two minutes

Measured data can also be downloaded from the HarvestLab 3000 sensor and saved to a computer for record-keeping purposes or to share.

*NOTE: Constituent measurements are only available with an additional purchased grass or corn calibration. The measured constituents, like protein and starch, depend on the purchased calibration.

Manure Sensing on slurry applicators

HarvestLab 3000 sensor mounted on a manure tanker

HarvestLab 3000 sensor mounted on a manure tanker

The HarvestLab 3000 sensor allows precise application of liquid organic fertilizer based on target and limit rate. This eliminates over fertilization (causing laid crops) and under fertilization (causing low yields). The system allows calculation of precise prescription maps to fill nutrient levels to the desired target, meaning the producer pays for quality not for quantity. Additionally, it helps to properly determine and document the applied nutrient levels to comply with legal regulations and cross compliance.

- John Deere Manure Sensing enables real-time constituent measurements in liquid organic fertilizers (hog, cattle, biogas)

- Automated and site-specific nutrient application and documentation

- Dry matter, nitrogen, ammonium, phosphorus, and potassium

Further information can be found in the John Deere Manure Sensing Sales Manual.

NOTE: John Deere Manure Sensing is available in selected countries.

Specifications

Contact Us

-

325 Walt Messick Road

Harrington, Delaware 19952

Phone: (302) 398-3729

Toll Free: (800) 237-1272