-

Menu -

Locations -

Search

John Deere 1725C Planter

Double tap to zoom

1725C Planter

Planting Equipment

Overview:

- 12-row, 36-, 38-, or 40-in. spacing (no lift-assist wheels)

- 16-row, 30-in. spacing (optional lift-assist wheels)

- Hydraulic wing locks for faster field-to-field transport

- Increased CCS tank from 35-to-55-bushel

- Available with optional ExactEmerge™ or MaxEmerge™ 5e Row Unit

- Folding staircase to prevent damage and improve accessibility

Get A Quote

Fields with asterisks* are required. Please email our helpful staff with any questions or comments using the contact form.

Loan Calculator

Use the Loan Calculator to help you determine the financing and payment options that are best for you.

**The accuracy of this calculator and its applicability to your circumstances is not guaranteed. You should obtain personal advice from qualified professionals. This information is provided for illustrative purposes only and does not constitute an application. This notice does not guarantee loan approval, nor is it an offer or commitment to make a loan to you on the above terms.

Send To A Friend

Fields with asterisks* are required. Your friend will receive an email that contains a reference to this page. Please send this email only to people you know who would be interested in this information.

Share This Product:

Features

1725C Planter Configurations

1725C 16Row 30 in. non-CCS planter in the field

1725C 16Row 30 in. non-CCS planter in the field

The 1725C planter is available in the following configurations:

- 1725C 12Row – 30 in.

- 1725C 12Row – 36 or 38 in.

- 1725C 12Row – 38 or 40 in.

- 1725C 16Row – 30 in

1725C 16Row 30 in. CCS planter in the field

1725C 16Row 30 in. CCS planter in the field

Before placing an order, please reference the Build and Price tool for any recent revisions to the below information.

Base Code |

Description |

355HH |

1725C 12Row 30 in. |

355JH |

1725C 12Row 36 or 38 in. |

355KH |

1725C 12Row 38 or 40 in. |

355LH |

1725C 16Row 30 in. |

Increase productivity with ExactEmerge™ trench delivery system and BrushBelt™ delivery system

It is very challenging to get the crop planted during the optimum planting window or as close to the optimum planting day as possible. Rate-of-yield loss accelerates greatly after the optimum window has passed. This is especially true in the northern U.S. and Canada. ExactEmerge maintains accurate speed placement at higher speeds; growers can avoid missing that peak planting time, thereby helping to get the highest crop yields.

Yield loss after optimum planting day

Yield loss after optimum planting day

With the BrushBelt trench delivery system, the spacing in the trench does not change from even to uneven terrain. This can be a problem with a traditional seed tube. Seed bounce and ricochet may occur as slopes increases, ultimately decreasing seed spacing performance.

The design of the BrushBelt system provides the best solution for the lowest release of seed to the bottom of the trench. The use of a brush provides the meter with an infinite amount of placement opportunities for each seed. This is what gives producers the confidence that every seed will have the desired spacing that a seed tube cannot provide.

Maintenance-free BrushBelt system

Maintenance-free BrushBelt system

When the brush comes around the pulley, it expands and allows the seed to be transferred from the bowl to the brush very easily. The brush then carries the seed down toward the trench, ensuring that there is no movement as it moves down the length of the cartridge.

Once the brush reaches the lower pulley, the BrushBelt system expands again to loosen the grip on the seed, and the centrifugal force releases the seed. Another advantage with the BrushBelt system and cartridge at all speeds up to 16.1 km/p (10 mph) is the ability to match the seed rearward trajectory to the forward ground speed of the planter. This provides a dead drop of the seed with no bounce and no roll at the bottom of the trench.

BrushBelt conditioner engages brush bristles

BrushBelt conditioner engages brush bristles

John Deere’s ExactEmerge cartridge is self-cleaning. When an operator uses seed treatments or is forced to plant in less than ideal soil conditions, the design of the trench delivery system sheds buildup from the BrushBelt. A brush conditioner is located at the bottom of the cartridge to remove remaining residue and prevent the bristles from sticking together.

Brush proximity helps clean sensor

Brush proximity helps clean sensor

Another advantage over a seed tube is that the BrushBelt system also acts as a cleaner to the seed sensor compared to a seed tube.

Sensors for trench delivery system

Sensors for trench delivery system

Reflective seed sensor

Reflective seed sensor

Sensor on trench delivery system

Sensor on trench delivery system

On all ExactEmerge row-units, each cartridge is equipped with sensors. As the seeds are being delivered through the BrushBelt delivery system controls, they pass the reflective seed sensor. The delivery system slides every seed past the seed sensor to read and send the signal to the controller. The seed sensor and design can provide sensor performance at higher seeds per second with no population adjustment as needed with seed tube sensors. This seed sensor data is actual row-unit performance data. In comparison, seed tube sensors add 10 percent population in soybean planting to adjust for the seeds missed due to placement within the seed tube. The BrushBelt system holds each seed in place until released in the trench, allowing the seed sensor a more accurate read.

BrushBelt removed from trench delivery system

BrushBelt removed from trench delivery system

The BrushBelt system requires no maintenance and has a wear life designed to match the wear life of the other wear components. Since operations vary, as do soils and field content, it is recommended to replace the BrushBelt after noticeable wear or decreased performance.

Changing the belt is easy. One latch removes the meter over the trench delivery system. Grab the cartridge by the grip and pull toward the body, releasing it from the electric motor fitting. Lift the trench delivery system up and remove the sensor wiring harness to completely pull the cartridge out of the row-unit.

There are two plastic covers that snap off to uncover the belt; remove the covers and then twist the circular spring tensioner dial with the yellow arrow on it to release the tension on the springs. Once tension has been removed, pull the belt out. It is also recommended to change the stainless-steel wear strip at this time as well, which also slides right out of place without the use of tools.

NOTE: It is recommended to use a talc/graphite mixture with ExactEmerge. Best results have been 80 percent talc and 20 percent graphite. For certain regions and territories, talc and talc/graphite mixes are restricted from use; in this case, use a wax-based fluency agent.

1725C Hopper Options with Electric Drives

2.7 bushel hopper available from the factory on 1725C planters

2.7 bushel hopper available from the factory on 1725C planters

Overview

John Deere is now offering four new 1725C non-CCS models with three hopper options installed at the factory. The 1725C models with hoppers and electric drives include: 12R30, 12R36/38, 12R38/40, 16R30. The three row hopper options from the factory are 1.6 bu MaxEmerge™ 5e or ExactEmerge™*, 2.7bu ExactEmerge, and 3.0 MaxEmerge 5e.

*ExactEmerge not available on 76.2 cm (30 in.) units

Benefits

- Enables ExactEmerge or MaxEmerge 5e

- Enables the full agronomic suite (pneumatic row cleaners, individual row hydraulic downforce, pneumatic closing wheels)

- Optional ExactRate Liquid Fertilizer

Adding electric drives to the 1725C line brings improved agronomics to even more of our farmers. Adding electric drives to the non-CCS models opens up ExactEmerge. Additionally, peanut farmers and those who cannot use a central commodity system now have access to electric drives through MaxEmerge 5e. The addition of electric drives minimizes skips and doubles, increases spacing accuracy, and enables turn compensations.

Easy fluid transfer with the ExactRate™ fluid transfer system

The ExactRate fluid transfer system pairs planters seamlessly with the ExactRate tractor tanks. It provides an easy connection point to allow transfer from the ExactRate tractor tanks back to the planter tank. This enables up 3785 L (1000 gal.)* of capacity on the tractor tanks.

*NOTE: 3785 L (1000 gal.) assumes capacity on the integrated 8RX Tractor tanks.

- Factory installed

- Designed and tested by John Deere to ensure the lines do not pinch when folding

- Easily attaches to the ExactRate tractor tanks

If pairing with 8RX ExactRate tractor tanks, an additional valve can be ordered to improve priming performance. Part AA110692 can be ordered through Service Parts. All planters come with the brackets and U-bolts shown in the following image.

Brackets and U-bolts on planter for ExactRate valve

Brackets and U-bolts on planter for ExactRate valve

1725C Planter - Integral stack folding frame

Convenient stack-folding design can be used rigid or flexible

Convenient stack-folding design can be used rigid or flexible

The 1725C stack-fold frame design can operate in both rigid-frame and flex-frame configurations. The frame has improved durability and Category 3/4N quick hitch compatibility. Color-coded hydraulic handles with an anti-slip grip for easy planter-to-tractor hook up was added. The 1725C utilizes a three-section frame that can flex up to 8 degrees up and 8 degrees down. The 1725C is not offered with markers.

The 1725C Stack-Fold Integral Planter is available in the following configurations: 12Row36, 12Row38, 12Row40 and 16Row30.

Category 3/4N hitch for quick hitch compatibility

Category 3/4N hitch for quick hitch compatibility

Color-coded hydraulic handles with an anti-slip grip for easy planter-to-tractor hookup

Color-coded hydraulic handles with an anti-slip grip for easy planter-to-tractor hookup

Stack-fold frame design

Stack-fold frame design

The 1725C 12Row36, 12Row38, and 12Row 40, and 16R30 are available without lift-assist wheels. This allows for increased maneuverability around tighter field conditions and bedded crops. Lift-assist wheels are an option for the 1725C 16Row30.

1725C 16-row frame

1725C 16-row frame

Vacuum run through the frame provides a cleaner look

Vacuum run through the frame provides a cleaner look

The vacuum is run through the planter frame. This cleaner frame design provides improved visibility when seated in the cab.

Hydraulic cylinder on 1725C frame for wing downforce/gull wing functionality

Hydraulic cylinder on 1725C frame for wing downforce/gull wing functionality

Optional wing downforce/gull wing is available on the 1725C. When traveling at speeds above 8.05 km/h (5 mph), row-unit downforce may be significant enough to overcome the frame’s wing weight, sacrificing ground contact and consistent depth. Hydraulic cylinders have been added to maintain force on the outer wings to keep desired depth. Operators can also pin the outer wings rigid with or without the wing downforce/gull wing option.

The same cylinders are used to enable the gull-wing feature on the 1725C. The gull wing flexes the outer wing up to 8 degrees upward, allowing for more vertical wing clearance.

Hydraulic locking mechanism for in-cab wing locking

Hydraulic locking mechanism for in-cab wing locking

An automatic hydraulic wing locking feature is available on the 1725C. Once the operator engages the frame-fold selective control valve (SCV), the hydraulics release the locking mechanism and the planter starts folding. This reduces trips up and down the tractor and provides for a much quicker folding and unfolding process.

Active pneumatic downforce compressor

Active pneumatic downforce compressor

Active pneumatic downforce is in base on the 1725C. This feature provides the proven downforce solution for growers to maintain consistent depths even at speeds up to 16.1 km/h (10 mph).

Increase overall productivity with Central Commodity System (CCS™) seed delivery system

1938 L (55 bu) CCS tank with LED tank lights

1938 L (55 bu) CCS tank with LED tank lights

Redesigned folding staircase and relocated blower

Redesigned folding staircase and relocated blower

Several improvements have been made to the 1725C CCS tank and surrounding areas. The redesigned folding staircase is ergonomically friendly and stays out of the way of obstacles while planting. This change leads to the larger 1938-L (55-bu) CCS tank to help reduce fill times and let operators get the planting done quicker. The CCS tank has been raised 16.5-cm (6.5-in.) for added clearance of tank clean out, and the CCS blower has been relocated to lessen noise in the cab. The raised CCS tank and relocated blower also provide better visibility to the center row units.

CCS seed delivery adds productivity through:

- Increased seed capacity

- Bulk fill capability

- Easy, thorough cleanout

Filling the tanks is convenient due to a central filling location. The staircase and railing provide access to the filling platform between the tanks. Additionally, each tank has an adjustable bin-level sensor to alert the operator when it is time to fill.

A light-emitting diode (LED) fill light package is included on machines equipped with CCS. This feature includes two LED lights conveniently mounted on the railings of the machine. The lights are turned on and off with their own switch located at the bottom of the staircase.

If the seed-carrying vehicle requires hydraulic power to run the unloading system, the auxiliary hydraulic coupler option is available. These couplers are located at the bottom of the staircase and can be coupled under pressure. The system has a separate system filter that ensures the planter hydraulic system remains free of contaminants.

Seed delivery process

The 1938-L (55-bu) CCS tanks allow operators to spend less time filling and more time planting.

The CCS seed delivery process relies on a hydraulically driven fan to move seed from the CCS tanks to the row-unit hoppers. A flow control valve and gauge, located near the tank, allows for the proper tank pressure setting based on seed type. For normal operation, the CCS functions of fan and agitator control, as well as bin level sensing alerts, are controlled by status of the height switch. The CCS functions are enabled when the machine is lowered and disabled when the machine is raised. In addition, the CCS functions can be engaged for CCS hose cleanout using the switch on the back of the planter when oil flow is present. On models with software-based CCS control, CCS functions can be enabled or disabled through software interface in the cab as well as the switch on the back of the planter.

Air from the fan pressurizes the CCS tanks and delivers seed to the seed hoppers. Airflow enters the seed tanks through a nozzle in the manifold which pressurizes the tank. The air then picks up seed and moves it out the other end of the nozzle into seed delivery hoses. These hoses route the seed toward the hopper. A small amount of seed is traveling in the delivery hoses only when needed.

The hopper fills with seed until the delivery hose (discharge elbow) is covered. Once the opening is restricted, seed flow through the hose stops. Air flowing to the row-unit travels into the hopper and is the source of air for the vacuum system. This provides a much cleaner air source than previous meter designs. As the seed is picked up by the meter and planted, the seed pool shrinks until the end of the delivery hose is uncovered. At that time, the airflow and seed delivery resume and the seed pool in the hopper is replenished.

CCS seed cleanout

Seed cleanout is easy with a CCS planter. The CCS tank has been raised 16.5-cm (6.5-in.) for added clearance of tank clean out. When finished planting, any remaining seed can simply be removed via access doors at the bottom of the CCS tank.

CCS seed delivery hoses are then purged with air from the CCS fan, and the excess seed is pushed to the individual meters. The vacuum meter door is opened and seed is removed with the supplied catch pan.

Small seed CCS components

Manifold nozzle and nozzle with cover installed

Manifold nozzle and nozzle with cover installed

Straight seed inlet installed in mini-hopper

Straight seed inlet installed in mini-hopper

CCS seed delivery system increases planting productivity across the approved crops listed above. While highly effective delivering seed from the CCS tanks to the vacuum meters, small or light seeds require two additional components to aid in proper seed delivery.

Manifold nozzle covers (clips) should be installed to ensure seed is adequately picked up into the air stream for delivery to the row-unit. Mini-hopper discharge elbows should also be changed from the standard elbow (holes) to the small seed elbow (slotted openings) when planting sorghum (milo) and small cotton.

Downforce system options

Individual Row Hydraulic Downforce (IRHD)

IRHD system

IRHD system

IRHD has been specifically designed to meet the needs of producers that are looking to adjust to the toughest field conditions and provide maximum yield potential from field to field, season after season. IRHD works as a closed-loop downforce system that reacts quickly on an individual row basis to changing soil conditions supporting increased ground contact, which can lead to improved seed depth consistency. When setting planter downforce margin, the system will apply the needed downforce by row to maintain ground contact. From the factory, the margin will be set at 45.4 kg (100 lb), changes may be required based on varying field conditions.

The system allows operators to maintain gauge wheel ground contact leading to desired seed depth placement. IRHD can adjust five times per second and make adjustments of 45.4 kg (100 lb) in less than a second. The system has a total range of applied downforce from 22.7 kg (50 lb) to 204.1 kg (450 lb) and utilizes the power beyond circuit on the tractor. IRHD is 58 percent faster than the active pneumatic downforce solution. Fast reaction and increased ground contact can lead to improved emergence. With uniform emergence, some studies have shown a yield impact from 5 percent to 9 percent.

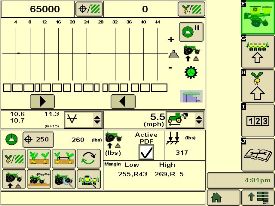

IRHD is controlled through the display with SeedStar™ 3 HP or SeedStar 4HP. As shown below, operators can view ground contact or applied downforce using the toggle button.

IRHD screen showing the ground contact graph through SeedStar 4HP

IRHD screen showing the ground contact graph through SeedStar 4HP

IRHD screen showing the applied downforce graph with SeedStar 4HP

IRHD screen showing the applied downforce graph with SeedStar 4HP

Hydraulically driven compressor

Pneumatic valve

Pneumatic valve

The hydraulically driven air compressor can deliver up to eight times the air flow when compared to the electric compressor, allowing for more and faster downforce changes to be made. This more robust design features a 37.8-L (10-gal.) storage tank across all models with active downforce.

At approximately 15.1 L/min (4 gpm), hydraulic demands are low and ties into the machine’s lift and Central Commodity System (CCS™) hydraulic circuit so it does not require any additional selective control valves (SCVs). The SeedStar XP, SeedStar 3 HP, and SeedStar 4 HP monitoring systems work with the compressor. SeedStar 3 HP and SeedStar 4 HP monitoring systems work with the compressor and valve assembly to regulate air to downforce springs, enabling the active control, pneumatic closing wheels, and pneumatic row cleaners.

Row-unit downforce planter run page

SeedStar XP downforce planter run page

SeedStar XP downforce planter run page

Active downforce control is integrated into SeedStar XP, SeedStar 3 HP, and SeedStar 4 HP monitoring systems.

Margin is the amount of weight riding on the depth gauge wheels that ensures desired firming of the seedbed as set by the operator.

Once a target margin has been defined, enter the value into the display and let active downforce do the rest. The system will actively adjust the air pressure in the air bags to maintain a constant margin across the planter. The changes in air pressure will change the amount of downforce placed on the row-unit, compensating and reacting for varying conditions through the field whether it is different tillage practices, soil types, or moisture.

Downforce and margin example

Downforce and margin example

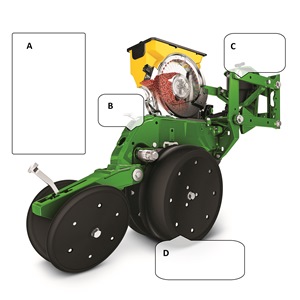

- A - Margin – amount of additional downforce applied to a row-unit above and beyond what is required for penetration to achieve planting depth. This additional weight will ride on the depth gauge wheels.

- 54.4 kg (120 lb) + 36.3 kg (80 lb) = 90.7 kg (200 lb) – 68 kg (150 lb) = 22.7 kg (50 lb) of margin

- B - Weight of row-unit - 54.4 kg (120 lb)

- C - Downforce – force that is applied to the row-unit by the air bag circuit - 36.3 kg (80 lb)

- D - Resistance from soil - 68 kg (150 lb)

Margin video references:

Using Active Pneumatic downforce

Pneumatic downforce spring

Pneumatic downforce spring

Each row-unit has a single rubber air bag located between the parallel arms. The air bags are hooked in parallel so that air can be added or released from all rows at once from one location.

The individual pneumatic downforce air bag assemblies, air compressor units, and 9.5-mm (3/8-in.) delivery lines are also available as an attachment for field conversion.

Active downforce compressor assembly

Active downforce compressor assembly

A hydraulically driven compressor works with the SeedStar XP, SeedStar 3 HP, and SeedStar 4 systems to automate downforce control. Just set the row-unit target margin value and the active pneumatic downforce system works automatically. The system will make sure the planter maintains this value, achieving precise soil penetration, and consistent planting depth, without sidewall soil compaction. From the factory, the system is set at 45.4 kg (100 lb) target downforce margin but may be modified for varying field conditions. This frees the operator from constantly making manual downforce adjustments as conditions change.

This system offers a split-rank control feature for 1795 and DB Split-Row Planters. On split-row planters, active downforce will control the front and rear rows independently. This compensates for differing downforce requirements between the ranks that can be caused by things like different tillage or insecticide attachments and will help maintain an accurate planting depth and consistent margin across all the rows.

Active pneumatic downforce is available as factory installed or as an attachment for field conversion.

Set point row-unit downforce

Pneumatic downforce control in GreenStar 2 Display

Pneumatic downforce control in GreenStar 2 Display

Air compressor mounted on 1775NT outer hitch

Air compressor mounted on 1775NT outer hitch

On set point, the air compressor will be mounted on the outer hitch or frame assembly. Since the electric air compressor assembly is mounted on the outer hitch (as noted in the picture above) or frame, adjustments for row-unit downforce and related system pressures will be made electronically with the GreenStar display.

When adjusting the amount of row-unit downforce using the GreenStar display, the operator will select the amount of downforce (kg [lb]) to be applied across the planter. Depending on the soil conditions at hand, the operator might need to adjust the relative amount of row-unit downforce being applied during the planting operation. The integrated pneumatic downforce controls within the GreenStar display will only allow for set-point operation and not automatic control as the planter is operating in different soil conditions. The pneumatic downforce system does not have the capability to automatically adjust downforce.

Pneumatic downforce provides convenient, simple adjustment of downforce for the whole planter from one location. The amount of downforce applied is infinitely adjustable from 6.8 to 181.4 kg (15 to 400 lb). Pneumatic downforce provides more consistent downforce throughout the range of row-unit travel than mechanical spring downforce systems.

Features include:

- 9.5-mm (3/8-in.) air delivery line instead of the 6.4-mm (1/4-in.) line used on model year 2010 and older planters.

- Air compressor assembly increased duty cycle. With this compressor, it provides a 47 percent increase in maximum air flow delivery compared to the prior air compressor.

- Pneumatic air bags with 9.5-mm (3/8-in.) air line inlets that have greater durability.

Pneumatic downforce compressor and gauge

Pneumatic downforce compressor and gauge

An improved compressor is used to charge the pneumatic system. This compressor can be located on the planter frame or in the tractor cab if desired. A gauge at the compressor indicates the amount of downforce being applied.

Integrated pneumatic downforce system

The functional features of the integrated system are the same as the standard pneumatic system, explained above, with the addition of control through the GreenStar display.

Heavy-duty adjustable downforce springs

Heavy-duty adjustable downforce spring

Heavy-duty adjustable downforce spring

Planter row-unit downforce is an important factor to ensure consistent and proper depth control. The heavy-duty adjustable downforce feature provides up to 181.4 kg (400 lb) of downforce. There are four settings available to allow the operator to choose the amount of downforce required for the condition: 0 kg (0 lb), 56.7 kg (125 lb), 113.4 kg (250 lb), and 181.4 kg (400 lb).

Easy Adjust row cleaners

Coulter combo row cleaner

Coulter combo row cleaner

Easy Adjust row cleaner

Easy Adjust row cleaner

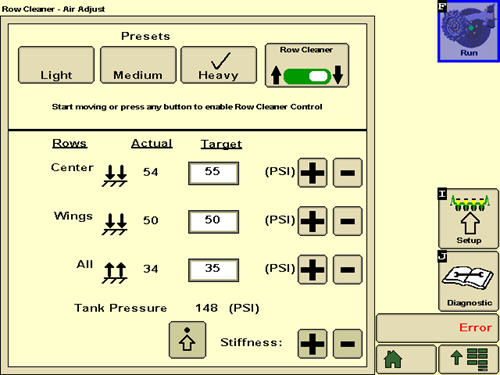

Easy Adjust row cleaner and coulter combo provides a pneumatic row tillage solution that is controlled from the seat of the tractor.

Every decision to make an adjustment during spring planting reduces the acres planted per day and can increase or decrease profitability. An adjustment that can be overlooked is row cleaners due to planter size, difficulty to make the adjustment, and varying conditions across fields and time.

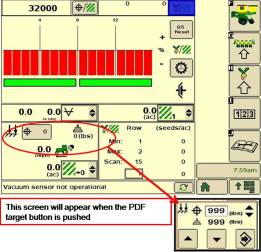

GreenStar™ 3 2630 Display view for row cleaners compatible with SeedStar™ 3 HP

GreenStar™ 3 2630 Display view for row cleaners compatible with SeedStar™ 3 HP

4600 CommandCenter™ Display and 4640 Universal Display view for row cleaners compatible with SeedStar 4HP

4600 CommandCenter™ Display and 4640 Universal Display view for row cleaners compatible with SeedStar 4HP

With the Easy Adjust row cleaners on ExactEmerge™ planters, operators now have a pneumatic solution to make on-the-go adjustments that is controlled directly from the seat of the cab. They can be raised from the cab as needed with the push of a button for wet areas, waterways, or end rows. For growers using SeedStar 3 HP, the row cleaners are completely integrated into the John Deere GreenStar 3 2630 Display as well as the Gen 4 4600 CommandCenter display or 4640 Universal Display. For growers using SeedStar 4HP, a 4600 CommandCenter display or 4640 Universal Display is required.

The Easy Adjust row cleaners have the capability to save three presets for varying ground engagement based on field conditions. The system is controlled in three sections: at each wing as well as the center (frame or wheel) track rows. The pneumatic lines use air from the active pneumatic downforce compressor, requiring no additional compressor to be installed on the planter. The Easy Adjust row cleaners utilize down and up force air bags. The adjustable air pressure setting for each bag allows the operator to set the ride of the row cleaner depending on the field conditions and the desired results. Making these on-the-go adjustments from tractor cab increases productivity and performance during planting.

For Easy Adjust row cleaner Precision Upgrade options, see the ordering guide.

The row cleaner-only option utilizes parallel linkage to provide the floating action growers require in their fields. Parallel linkage allows for the unit to float up and down in the situation of hills or hard objects. The cleaner and coulter combo does not have parallel linkage, however, the row cleaners have floating rings installed to help provide the same benefits.

The row cleaners utilize the field-proven SharkTooth® design. Row cleaners play a major role in maximizing yield toward uniform emergence, reducing row-unit bounce, and maintaining proper depth. The Easy Adjust row cleaners provide growers with quick and stress-free solutions to customizing the planter in variable field conditions. They are available on most ExactEmerge and MaxEmerge 5e equipped planters.

SharkTooth is a trademark of Yetter Manufacturing Incorporated.

Mobile row-unit runoff

Row Runoff diagnostic test

Row Runoff diagnostic test

The test functions from a mobile device

The test functions from a mobile device

Determine optimum settings without being in the cab

Determine optimum settings without being in the cab

The first day of planting season can be as productive as the last with mobile row-unit runoff. The mobile row-unit runoff activation on the planter main controller (PMC) allows operators to make adjustments to maximize row-unit performance from a mobile device at the rear of the planter for both preseason and in-season use - all enabled through the Equipment Mobile app.

Mobile row-unit runoff allows growers to perform test-stand functions from a mobile device connected to the planter.

The row runoff test provides complete diagnostic checks both preseason and in season. With the row-unit runoff test, the operator can make adjustments from the mobile device, including vacuum pressure, to determine the optimum meter and vacuum settings. This app functionality will help avoid making trips to the cab while validating meter performance.

During preseason planter inspections and set up, utilize the meter performance test to validate meter accuracy, similar to a test stand without leaving the farm. Test all systems on the planter, not just the meter, providing confidence that all planter systems are ready to plant. Reports are generated from the test providing information the operator can save and send for future reference.

Before heading to the field, the operator will benefit from knowing the best row-unit and vacuum settings for each variety selected to plant that spring.

Watch this video to see mobile row-unit runoff in action.

Mobile row-unit runoff will work with any model year 2015 or newer ExactEmerge™ or MaxEmerge™ 5e equipped planter. Mobile row-unit runoff can be added with attachment AA93169.

For model year 2018 and newer ExactEmerge planters, mobile row-unit runoff is included in base equipment. For model year 2020 and newer MaxEmerge 5e planters, mobile row-unit runoff is included in base equipment. For planters not equipped from the factory, mobile row-unit runoff can be added with attachment AA93169. A mobile row-unit runoff and Easy Fold package can be added with attachment AA97849 (only available with 1775NT and 1795 Planters with a 2-point hitch and model year 2019 and newer DB Planters with Gen 4 based frame folding).

NOTE: Mobile runoff utilizes the Equipment Mobile app available on select iPad® tablets, iPhone® smartphones, and Android™ devices.

Mobile row-unit runoff and Easy Fold aftermarket for field conversion kits

The below software bundles include the functionality explained above for machines not ordered with the feature from the factory. Compatible machines include all the necessary sensors and harnesses needed to make the feature function. The attachment part is software only. Follow the mobile runoff ordering and software push guide below for ordering and installation.

SeedStar™ 3 HP conversion to SeedStar 4HP

Mobile runoff ordering and software push guide

iPad and iPhone are trademarks of Apple Inc. Android is a trademark of Google LLC.

Achieve accuracy with curve compensation

Curve compensation with planters

Curve compensation with planters

Terraces or waterways are two of many field obstacles that make planting on a curve challenging. When planters utilize drive shafts, they are not able to control each individual row-unit; as a result, planting on a curve presents an issue of maintaining 100 percent population. Since the inside rows are moving slower than the outside rows, the inside rows will be overpopulated while the outside rows are underpopulated.

With ExactEmerge™ planters and equipped MaxEmerge™ 5e planters, the curve compensation feature allows each row to receive an individual signal based on the speed at which the row-unit is moving, maintaining the correct population across the width of the planter. Without curve compensation, there could be as much as a 24 percent drop in population accuracy, which is equivalent to 8,600 seeds per acre when planting at 36,000 seeds per acre. Curve compensation measures acceleration within the main planter controller and utilizes speed inputs to ensure each row has the desired population accuracy.

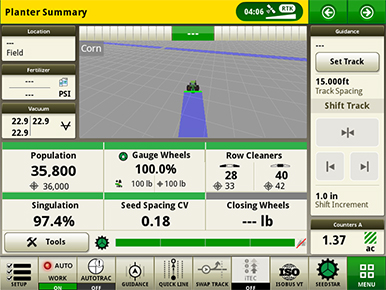

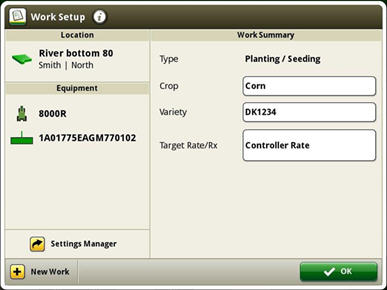

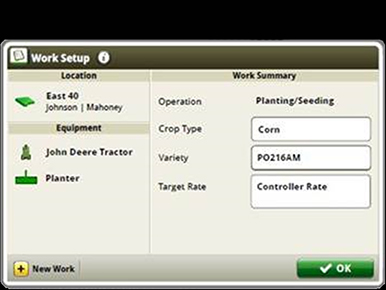

SeedStar™ 4HP monitoring system – see speed meet accuracy in real time

Have you wanted to view more than one planter chart at once? SeedStar 4HP gives you multiple views and configurations in one simple overview page to fit your preferences. You can complete the simplified setup from the Work Setup page instead of having multiple applications to open.

SeedStar 4HP is designed to optimize the in-cab monitoring experience exclusively on the Gen 4 4600 CommandCenter™ display or 4640 Universal Display for growers with ExactEmerge™ planters and MaxEmerge™ 5e planters. With SeedStar 4HP, operators will easily see key planter information with customizable run pages, zoom functionality, and simultaneous graph and performance measurements. SeedStar 4HP is included in base on all model year 2018 ExactEmerge and MaxEmerge 5e planters.

Features overview:

- View multiple planters' at-a-glance bar charts simultaneously

- Three default planter run pages show key planter functions in easy-to-view layouts

- Highly configurable run pages allow SeedStar modules to be customizable

- Zoom feature allows quick row-by-row detailed information

- View dual bar graphs to see multiple planter details at one time

- SeedStar application to make adjustments to planter functions

- Simplified setup through the work set-up page

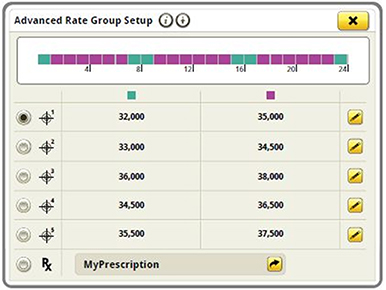

- Advanced rates allow up to six different rates across 48 rows

- The SeedStar 4HP monitoring system requires the Gen 4 4600 CommandCenter or 4640 Universal Display. These displays allow the operator to benefit from the updated interface, enhanced processing speeds, and easy setup (learn more here).

SeedStar 3 HP conversion to SeedStar 4HP with mobile row-unit runoff aftermarket for field conversion kits

Growers who are currently running model year 2017 planters, model year 2017 and newer Precision Upgrades, or model year 2017 and newer custom-built planters with the SeedStar 3 HP monitoring system can upgrade to the SeedStar 4HP monitoring system with mobile row-unit runoff. The attachment part, AA100382, is software only. The Gen 4 display software version will need to be 19-1 or newer and will require planter apps. Follow the mobile runoff ordering and software push guide below for ordering and installation. Retrofitted planters and custom-built planters will also require the John Deere Connect Mobile kit, 0048PC, from the Precision Ag Technology Price Pages and wiring harness AA83662 to enable the mobile row-unit runoff feature. Please reference Parts Advisor and DTAC Solution 105181 for model-specific mounting brackets. SeedStar 4HP requires the Gen 4 4600 CommandCenter v2 display or 4640 Universal Display.

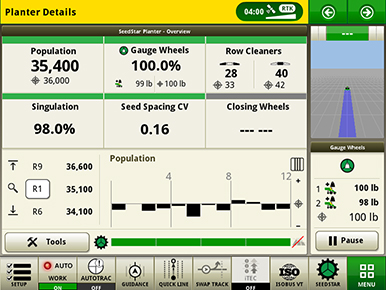

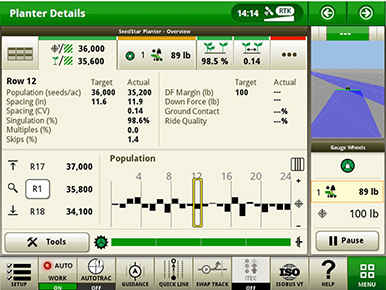

Default planter run pages

Planter summary default run page

Planter summary default run page

Planter overview default run page

Planter overview default run page

Planter details default run page

Planter details default run page

Three default run pages show key planter functions in different views to give fast and easy access to important planter information.

Custom run pages

Customizable run pages

Customizable run pages

There are customizable run pages that allow the operator to build pages that fit their operation with different modules, like the example shown above.

Zoom functionality

Zoom feature showing a group of rows

Zoom feature showing a group of rows

Zoom feature showing a single row

Zoom feature showing a single row

The zoom feature allows the operator to touch a section or row of the planter and get detailed information quickly.

Dual bar graphs

Dual bar graph showing singulation and population simultaneously

Dual bar graph showing singulation and population simultaneously

Dual bar graphs allow operators to view multiple planter details at one time.

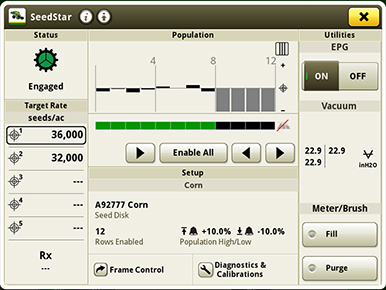

SeedStar application page

SeedStar application run page

SeedStar application run page

In the SeedStar application, many adjustments can be made, including manually activating section control. SeedStar 4HP allows up to 48 individual row sections. There are several setup features such as crop, seed disk, number of rows being planted, population alarms, and limits. Seed rates can be modified, electric power generation (EPG) can be turned on or off, vacuum can be adjusted, and the fill and purge functions can be used from the SeedStar application. Frame control, as well as diagnostics and calibrations, can be accessed at the bottom of the screen.

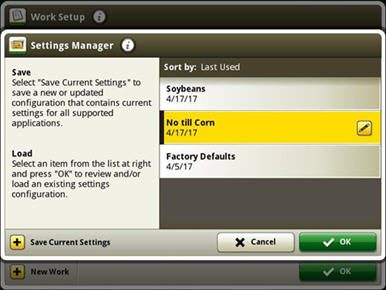

Settings Manager in SeedStar 4HP

Access Settings Manager on the Work Setup screen

Access Settings Manager on the Work Setup screen

Settings Manager screen

Settings Manager screen

Reduce set-up time between changing crops or field conditions by recalling saved settings used previously with Settings Manager, included with every SeedStar 4HP system. This feature allows saving and recalling planter and tractor settings for optimum performance in different conditions.

Settings Manager can be used to save all the adjustment and inputs associated to a particular crop or condition. An example would be to store all population rates, downforce pressure, row cleaner adjustments, and closing wheel settings for planting corn and storing a separate, unique set of adjustments for soybeans. In addition, Settings Manager stores tractor settings such as selective control valve (SCV) flow and detents, infinitely variable transmission (IVT™) settings, eco modes, and more.

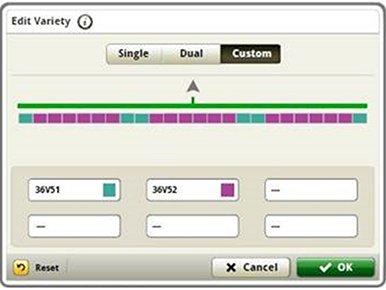

Custom rates in SeedStar 4HP

Variety set-up page

Variety set-up page

Rate set-up page

Rate set-up page

Group rate set-up page

Group rate set-up page

Custom rates allow for individual row population control and row-by-row documentation where up to six different rates can be assigned across an up to 48-row planter. This allows growers interested in planting seed corn with ExactEmerge or MaxEmerge 5e the capability to assign specific populations to male and female rows for planting. This feature can also be used to create tram lines or other applications where custom rates by row are needed.

NOTE: Individual rates are tied to varieties, so each individual rate needs a unique variety name.

NOTE: Advanced rates are not compatible with prescriptions or they cannot be run at the same time.

Compatibility

| SeedStar 4HP compatibility | |

| Planters | All models ordered with ExactEmerge or MaxEmerge 5e row-units NOTE: Precision Upgrades are equipped with SeedStar 3HP only but can be upgraded by purchasing part number AA100382. |

| Displays | Gen 4 4600 CommandCenter equipped with Version 2 Processor or 4640 Universal Display Dual-display mode is compatible with mid model year 2019 planter software. |

| John Deere Active Implement Guidance™ | Compatible with SeedStar 4HP on Gen 4 displays with VT mode and required activations and subscriptions |

| AutoTrac™ Implement Guidance | SeedStar 4HP is compatible with AutoTrac Turn Automation and AutoTrac Implement Guidance; not compatible with electric drive planters larger than 48 rows. |

| AutoTrac Turn Automation | SeedStar 4HP is compatible with AutoTrac Turn Automation and AutoTrac Implement Guidance; not compatible with electric drive planters larger than 48 rows. |

Additional information

For additional information on feature functionality on the Gen 4 Display, visit the links below:

YouTube is a trademark of Google LLC.

Specifications

Key Specs

| Number of rows | 12 |

|---|---|

| Row spacing | 76.2 cm 30 in. |

| Frame - Fold configuration | Stack-folding |

| Frame - Flexibility | Up: 10 degree (angle) Down: 7 degree (angle) |

| Row unit seed hoppers | Mini-Hoppers: MaxEmerge 5e: 56.4 or 105.7 L 1.6 or 3.0 bu ExactEmerge: 95.1 L 2.7 bu |

| Seed Meters | Base Vacuum |

Rows and Row Spacing

| Number of rows | 12 |

|---|---|

| Row spacing | 76.2 cm 30 in. |

Frame

| Fold configuration | Stack-folding |

|---|---|

| Frame tube size | |

| Fold-and-go from tractor cab | |

| Flexibility | Up: 10 degree (angle) Down: 7 degree (angle) |

Hitch

| Base | |

|---|---|

| Optional | |

| Rear hitch |

Lift System

| Type | Integral or semi-integral |

|---|---|

| Number of cylinders |

Tires

| Base | 12.5L-15SL 20 ply implement: 303 kPa 3.0 bar (44 psi) 7.60-15 8 ply implement: 359 kPa 3.6 bar (52 psi) 7.6-15 6 ply - traction: 276 kPa 2.8 bar (40 psi) |

|---|---|

| Optional | |

| Quantity |

Row Units

| Type | ExactEmerge™ row units or MaxEmerge™ 5e row units |

|---|---|

| Opener | Tru-Vee Double Disk |

| Depth gauging | |

| Adjustment | |

| Walking wheels | |

| Row unit seed hoppers | Mini-Hoppers: MexEmerge 5e: 56.4 or 105.7 L 1.6 or 3 bu ExactEmerge: 95.1 L 2.7 bu |

| Row unit down force | Adjustable heavy-duty ---- Active pneumatic downforce or individual row hydraulic downforce (IRHD) |

| Scrapers, opener blades | |

| Seed tube sensors |

Seed Meters

| Base | Vacuum |

|---|---|

| Optional | |

| Finger pickup | |

| Radial bean meter | |

| Central Commodity System | Seed capacity 1938 L 55 bu |

Drive System

| Base | Electric drive: EPTO only: 56 V |

|---|---|

| Optional | |

| Number of drive wheels | |

| Drive wheel disconnect | |

| Counter shaft | |

| Drill shaft | |

| Seed transmission | |

| Transmission combinations |

Markers

| Type | |

|---|---|

| Control | |

| Marker disk | |

| Shear bolt protection | |

| Less marker option |

Closing System

| Rubber tire closing system | |

|---|---|

| Cast iron closing system |

Herbicide and Insecticide

| Insecticide only hopper | |

|---|---|

| Herbicide only hopper | |

| Insecticide and herbicide hopper |

Liquid Insecticide System

| System available | |

|---|---|

| Tank capacity |

Seed Monitor System

| Base | SeedStar™ electronic system |

|---|---|

| Optional |

Tillage Attachments

| Unit-mounted coulter | |

|---|---|

| Frame-mounted coulter | |

| Bubble blade | |

| .63-in. fluted blade (25 flutes) | |

| .7-in. fluted blade (13 flutes) | |

| 1-in. fluted blade (8 flutes) | |

| Row tillage support hanger | |

| Tine tooth | |

| Cons. furrower w/ leading cutout blade | |

| V-wing bed sweeps | |

| Row cleaner | |

| Row cleaner - unit-mounted coulter | |

| Row cleaner - unit-mounted DD fert. opener |

Fertilizer

| Onboard / towed / tractor tanks | |

|---|---|

| Tank capacity | |

| Fixed-rate application | |

| Variable-rate application | |

| Pump type | |

| Pump rate | |

| Fertilizer opener type | |

| Flow divider distribution system | |

| Pressure manifold distribution system | |

| Dry fertilizer | |

| ExactRate Fluid Transfer System |

Dimensions

| Transport width (with markers) | |

|---|---|

| Transport width (without markers) | |

| Transport length | |

| Transport height | |

| Transport weight | |

| Transport underframe clearance | |

| Field operation height | |

| Field operation width | |

| Field operation length |

Ag Management Solutions

| Map-based seeding | |

|---|---|

| Field documentation | |

| Parallel tracking |

Additional Information

| Recommended tractor horsepower | Vacuum system hydraulic drive: horsepower required: 4.5-10.4 kW 6-14 hp Minimum tractor size: 201 kW 270 hp Tractor recommendation: Current model (minimum) 8430 MFWD with dual rear tires and 20 front weights. |

|---|---|

| Recommended tractor hydraulics | Hydraulic oil required to operate the planter: 227 L/min 60 gpm Hydraulic system standby pressure: 15,513 kPa 155 bar (2250 psi) Hydraulic system working pressure: 20,684 kPa 207 bar (3000 psi) Hydraulic system burst pressure: 82,737 kPa 827 bar (12,000 psi) |

| Warranty length | |

| Date collected |

Contact Us

-

325 Walt Messick Road

Harrington, Delaware 19952

Phone: (302) 398-3729

Toll Free: (800) 237-1272