-

Menu -

Locations -

Search

John Deere D625 Draper

Double tap to zoom

D625 Draper

Windrowers and Draper Platforms

Overview:

- 25 ft. (7.6 m) cut width

- Compatible with W200M, W235M, W235R and W260R

- Hydraulic tilt John Deere cutter bar

- Ground speed matching

- Integrated controls

Get A Quote

Fields with asterisks* are required. Please email our helpful staff with any questions or comments using the contact form.

Loan Calculator

Use the Loan Calculator to help you determine the financing and payment options that are best for you.

**The accuracy of this calculator and its applicability to your circumstances is not guaranteed. You should obtain personal advice from qualified professionals. This information is provided for illustrative purposes only and does not constitute an application. This notice does not guarantee loan approval, nor is it an offer or commitment to make a loan to you on the above terms.

Send To A Friend

Fields with asterisks* are required. Your friend will receive an email that contains a reference to this page. Please send this email only to people you know who would be interested in this information.

Share This Product:

Features

Interchangeable with John Deere rotary platforms

D600 Draper and interchangeable rotary platform

D600 Draper and interchangeable rotary platform

D600 Draper has an interchangeable rotary platform:

- Interchangeable on W200M and R Series units in 30 minutes or less

- Growers can use one traction unit for harvesting both small grains and hay

Higher productivity with center-driven belts

Center-driven belts

D600 Draper on W235 Windrower

D600 Draper on W235 Windrower

- Deliver increased torque

- Enable greater productivity with minimal belt slippage

- Increase performance in heavy crop conditions

Red circles point out the location of the belt drive motors

Red circles point out the location of the belt drive motors

- Draper belts on the D600 are driven from the center of the platform

- Delivers increased belt performance compared to drapers with end-driven belts

Belt drive motors

Motor driving the left-hand belt

Motor driving the left-hand belt

Motor driving the right-hand belt

Motor driving the right-hand belt

Due to the motors pulling the belt (instead of pushing in an end drive system), there is less slack in the belt. This delivers an increase in belt torque.

As a result, producers experience minimal belt slippage and increased performance in heavy crop conditions due to the center-driven belt system.

Strong, positive-feeding reel handles all crop conditions

D600 Draper

D600 Draper

The D600 Series includes an improved reel that increases durability in heavy crop conditions. The dual drive offers more versatility for operators to match their crop conditions and offers more reel torque for heavy crop conditions. The system can be quickly reconfigured by changing quick couplers to offer a series configuration for a higher reel speed to meet the needs of lighter crop conditions.

The cam reel allows the reel to efficiently lift crop across the cutterbar and release it onto the draper belts.

D600 Draper teeth

- Easy reel tooth replacement is done with a 90-degree turn using a wrench. It allows the reel tooth to be removed and replaced.

- Additional teeth can be added at any location along the extruded tooth bar.

John Deere parts and service support provide uptime for a timely harvest

Sales, parts, and service support from a local John Deere dealer offers overnight parts delivery and a well-trained support staff.

Draper hydraulic pump control logic delivers constant header speed

D600 Draper on windrower

D600 Draper on windrower

The draper hydraulic pump control adjusts knife, belt, and reel speeds to match the ground speed. This provides consistent feeding as you move through the field.

Hydraulic deck shift (double swath package)

John Deere D625, D630, and D636 Drapers can windrow out of the center, right, or left ends of the draper with the press of a button using the hydraulic shift option (double swath package).

- Larger windrows to match combine or self-propelled forage harvester

- Match narrower-width drapers with higher-capacity harvesting

- Place higher-density windrows in front of harvesters when yields are low

- Discharge two windrows side by side for uniform combine or forage harvester feeding

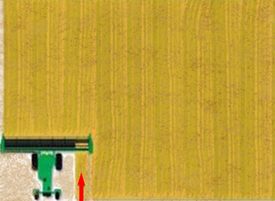

First pass with right discharge

First pass with right discharge

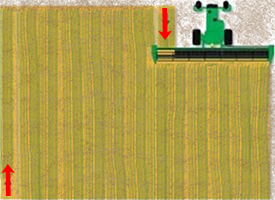

Second pass with right discharge

Second pass with right discharge

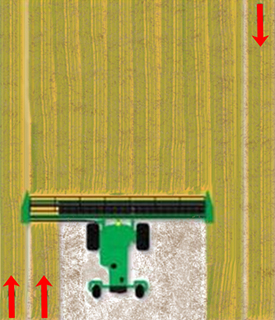

Third pass with left discharge

Third pass with left discharge

Center discharge

Center discharge

Specifications

Key Specs

| Cutterbar - Type | Dual knife |

|---|---|

| Cut width (length) | 6.1 m 20 ft |

| Reel type | Pick up cam four-position adjustable release |

| Fingers | HD Plastic |

| Belt width | Wide rubber skim-coated 710-ml (24-oz) drapers: 1,067 mm 41.6 in. |

| Platform length | 6.5 m 21.3 ft |

| Overall operating depth | With crop dividers 2.6 m 21.3 ft |

| Transport width, field position | 6.5 m 21.3 ft |

| Transport width on wheel, less dividers | 2.5 m 8.1 ft |

| Transport length, hitch extended |

Cutterbar

| Type | Dual knife |

|---|---|

| Cut width (length) | 6.1 m 20 ft |

| Knife drive | Hydraulic motor to enclosed heavy-duty wobble box |

| Knife speed | 700-850 cycles/min 1,400-1,700 spm |

| Stroke length | |

| Cutterbar tilt | Standard hydraulic Optional mechanical (7.5 to 17.0 degree lift) |

Reel

| Reel type | Pick up cam four-position adjustable release |

|---|---|

| Number of bats | 6 bats standard 9 bats optional, single span, capped ends |

| Fingers | HD Plastic |

| Diameter | 1,650 mm 65 in. |

| Height control | Hydraulic |

| Speed control | Hydraulic with header index |

| Reel lift | Hydraulic |

| Reel fore and aft | Hydraulic |

| Reel resume | |

| Reel reverse | |

| Operating speeds | 0-85 rpm |

| Operating speeds (54-inch reel) |

Draper and decks

| Belt width | Wide rubber skim-coated 710-ml (24-oz) drapers: 1,067 mm 41.6 in. |

|---|---|

| Delivery opening width | |

| Delivery opening height | |

| Cleat height | |

| Draper drive | |

| Operating speed | 0-225 m/min 0-742 fpm |

| Speed control | Hydraulic from cab |

| Remote canvas speed control | |

| Deck tilt | |

| Deck extensions |

Header height sensing

| Type | |

|---|---|

| Header height sensing on the ground | Float springs on traction unit |

| Header height sensing off the ground | Return to cut height standard Gauge wheels optional |

Auxiliary top auger

| Type |

|---|

Dimensions

| Platform length | 6.5 m 21.3 ft |

|---|---|

| Overall operating depth | With crop dividers 2.6 m 8.7 ft |

| Operating width (field) | |

| Transport width (reel fully retracted) | |

| Transport width, field position | 6.5 m 21.3 ft |

| Transport width on wheel, less dividers | 2.5 m 8.1 ft |

| Transport height | |

| Transport length, hitch extended | ---- |

Weight

| Approximate weight (base platform without reel) | |

|---|---|

| Approximate weight (base platform with reel) | 1,544 kg 3,400 lb |

| Approximate weight (with transport) |

Center opening / crop delivery

| Center opening width between belts | 1,720-1,950 mm 67.1-76.7 in. |

|---|---|

| Back sheet opening | |

| Deck shift / double windrow capability (manual / hydraulic / not available) |

Gauge wheels and transportation

| Gauge wheels | |

|---|---|

| Integrated slow speed transport system |

Additional information

| Date collected |

|---|

Contact Us

-

325 Walt Messick Road

Harrington, Delaware 19952

Phone: (302) 398-3729

Toll Free: (800) 237-1272