-

Menu -

Locations -

Search

John Deere 772 SPFH Corn Header

Double tap to zoom

772 SPFH Corn Header

Rotary Harvesting Heads

Overview:

- 12-row, large-drum head with a working width of 29.5 ft

- Matches the capacity of the new 9000 series for more throughput

- Optional AutoTrac™ RowSense™ integrates GPS data with row sensors for the ultimate in harvesting efficiency

Get A Quote

Fields with asterisks* are required. Please email our helpful staff with any questions or comments using the contact form.

Loan Calculator

Use the Loan Calculator to help you determine the financing and payment options that are best for you.

**The accuracy of this calculator and its applicability to your circumstances is not guaranteed. You should obtain personal advice from qualified professionals. This information is provided for illustrative purposes only and does not constitute an application. This notice does not guarantee loan approval, nor is it an offer or commitment to make a loan to you on the above terms.

Send To A Friend

Fields with asterisks* are required. Your friend will receive an email that contains a reference to this page. Please send this email only to people you know who would be interested in this information.

Share This Product:

Features

Fast-turning saw blades cut all kinds of crop

Saw blades with changeable segments

Saw blades with changeable segments

The saw blades of John Deere rotary crop headers cut quickly and thoroughly at a high speed of rotation. As the fast-turning blades cut the full width, crops can be harvested regardless of the row spacing. Thanks to this row-independent harvesting technology, the field can be worked from any side, which is particularly important for down crop.

The fast-turning saw blades allow crops with a lot of weeds to be harvested easily. Besides maize, a wide range of crops such as sorghum, whole crop silage, oilseed, canola, pampas grass, and miscanthus can be harvested.

Key features:

- Fast turning saw blades can cut in difficult harvesting conditions to give the operator increased uptime.

- Headers can be used in various stemmed crops and there is no need for extra headers, which saves on the cost of operation.

Intake fingers and gatherer drums for secure crop guidance

Intake fingers push every plant into the gatherer drum

Intake fingers push every plant into the gatherer drum

Plant pushed into the gatherer drum

Plant pushed into the gatherer drum

After the fast-rotating blades cut the crop, the intake fingers push the plants into the gatherer drums that rotate in the same direction at low speeds. Every plant is pushed into the teeth of the gatherer drum. The specially designed shape of the teeth ensures that both small and large plants are conveyed in a secure way.

In the machine, the plants are taken off the back of the gatherer drum by scrapers. Depending on the width of the header, they are forwarded to the cross-feed drums or immediately fed into the angled feed drums in the middle of the machine.

Key feature:

- Every plant is individually and securely pushed into the gatherer drum (Performance).

Deflectors guide the plants to the rotors

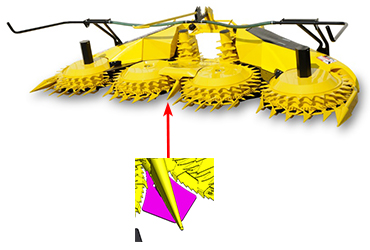

Deflector plates (purple) on the header

Deflector plates (purple) on the header

Additional deflector plates (purple) guide the crop toward the blades. This results in a more even stubble height.

Advanced Header Control (AHC) sensors

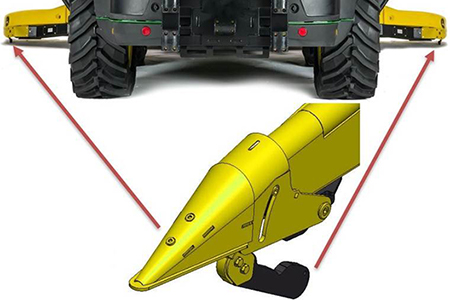

AHC sensors on the header

AHC sensors on the header

The AHC sensors are located at the two outermost points from the header. The sensors continuously scan the ground and quickly adjust the height and inclination of the attachment. This quick adjustment guarantees a constant stubble height.

The AHC sensors are optional equipment for eight-, 10-, and 12-row machines.

Third header height sensor

Third height sensor on the header

Third height sensor on the header

For eight-, 10-, and 12-row machines, the third sensor is optional equipment. The third sensor is only available in combination with RowSense™ system as it is installed in the central RowSense pointer.

The two-sensor Advanced Header Control (AHC) does a good job in most conditions. The optional third sensor is needed in extremely uneven terrain or on wide headers.

Lengthwise feeding for optimal chopping quality

Lengthwise feeding provides an even cut

Lengthwise feeding provides an even cut

Bundled, lengthwise feeding toward the feed rolls

Bundled, lengthwise feeding toward the feed rolls

The header bundles the harvested crop perfectly and feeds it to the chopping unit of the self-propelled forage harvester (SPFH) lengthwise for an even cut. Only even, lengthwise feeding allows for the full use of the power installed on the SPFH.

Even chopping of the crop

Even chopping of the crop

Key feature:

- Bundling of lengthwise stalks is the basis for perfect chopping quality (Performance).

Specifications

Contact Us

-

325 Walt Messick Road

Harrington, Delaware 19952

Phone: (302) 398-3729

Toll Free: (800) 237-1272